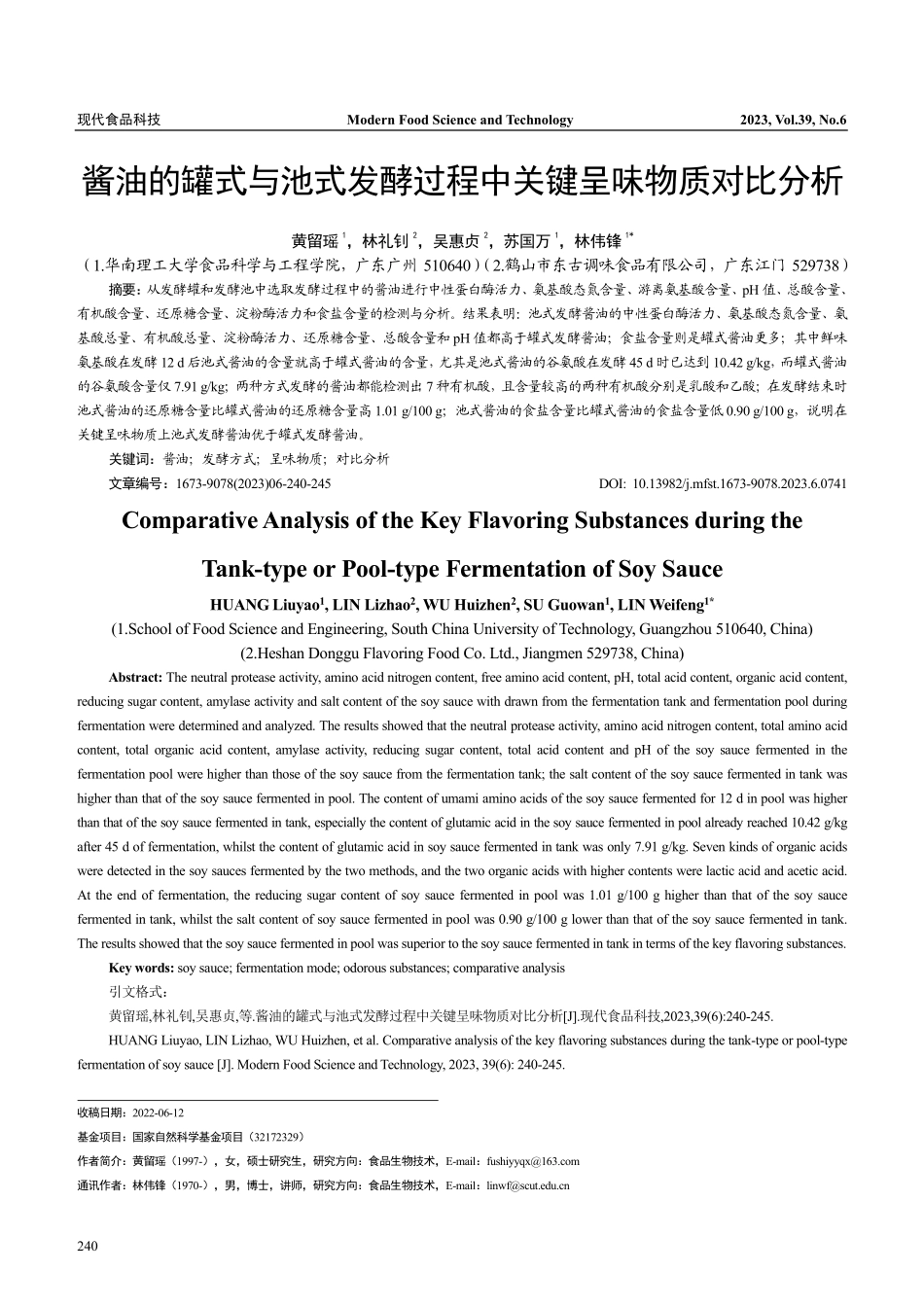

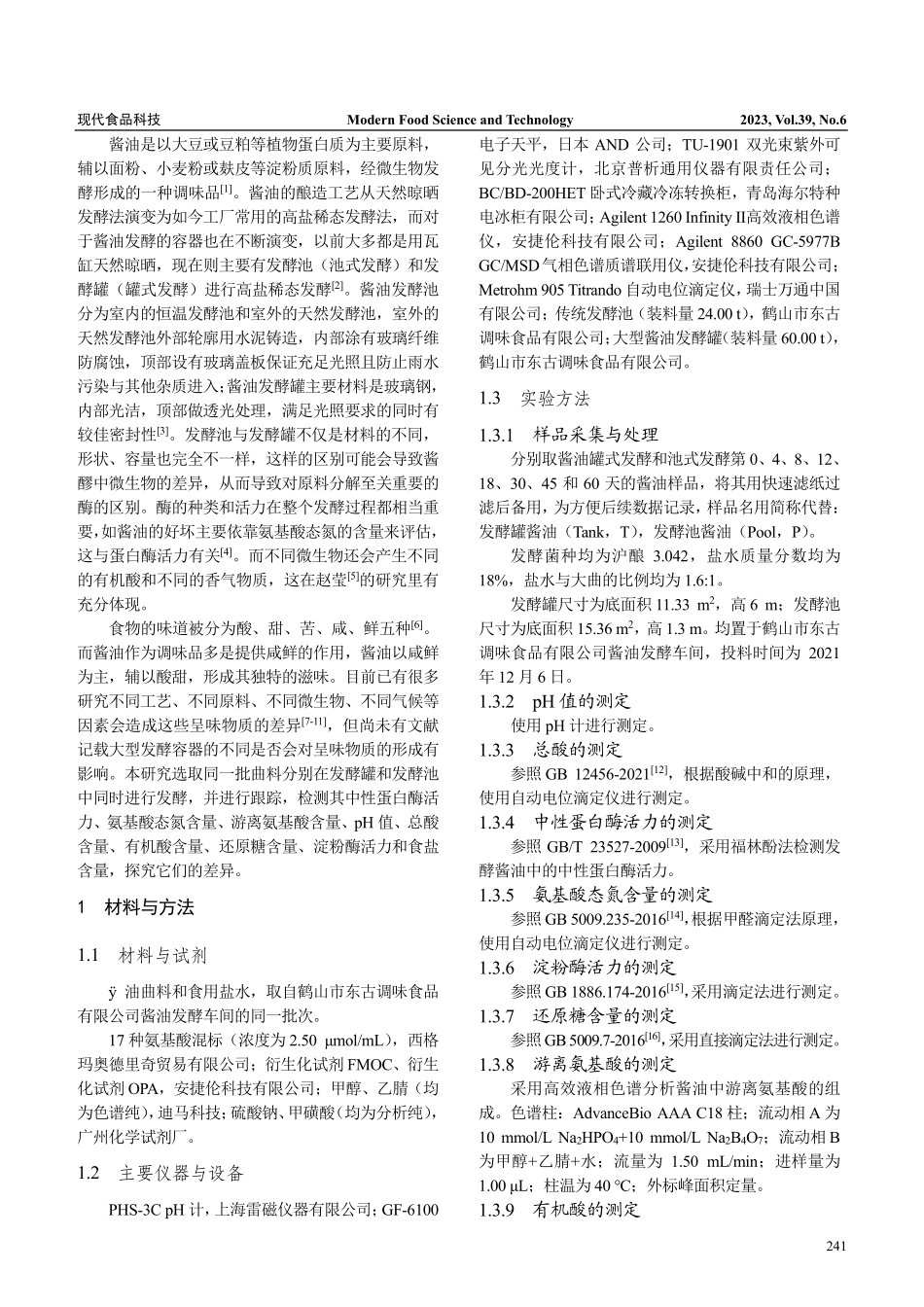

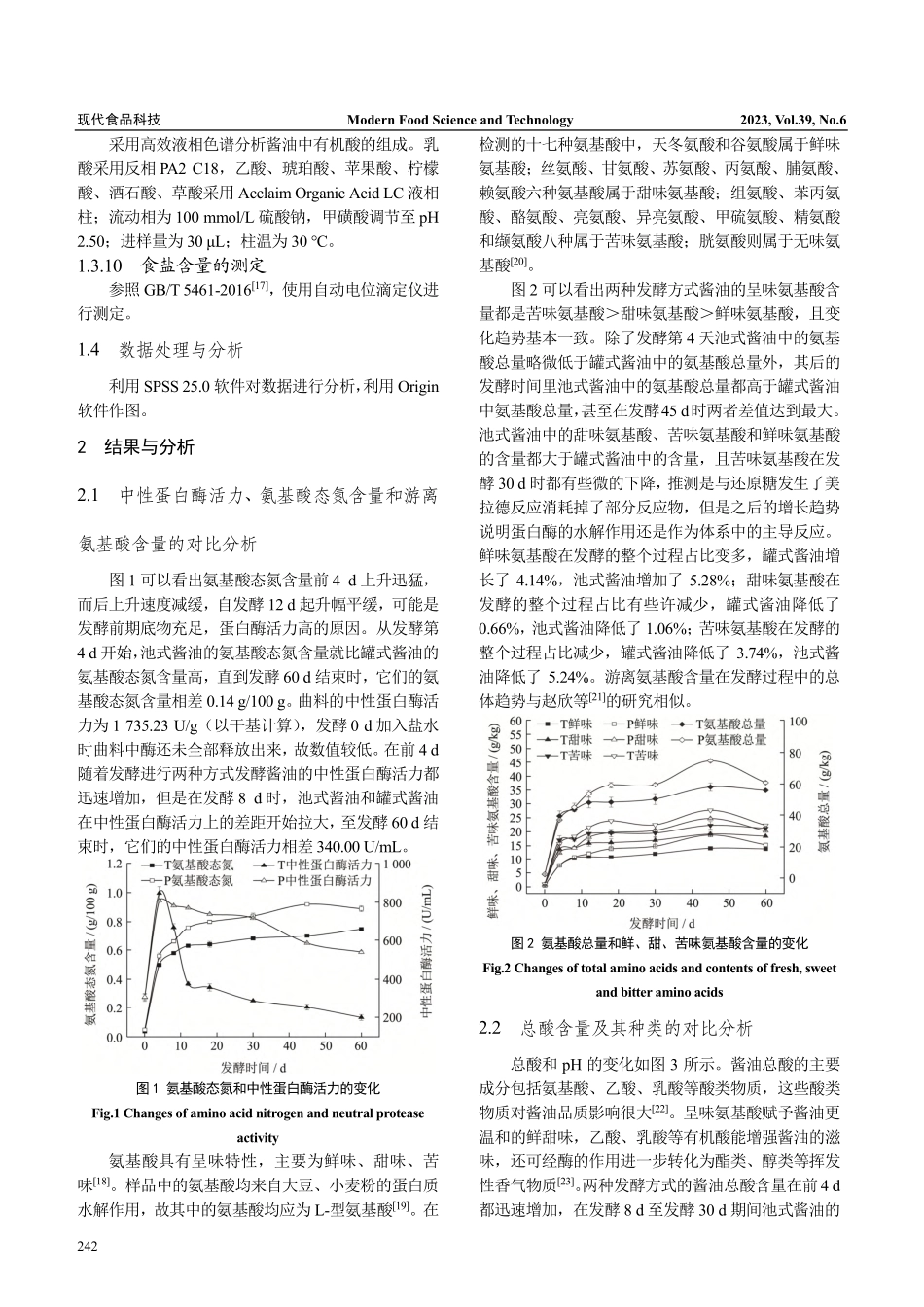

现代食品科技ModernFoodScienceandTechnology2023,Vol.39,No.6240酱油的罐式与池式发酵过程中关键呈味物质对比分析黄留瑶1,林礼钊2,吴惠贞2,苏国万1,林伟锋1*(1.华南理工大学食品科学与工程学院,广东广州510640)(2.鹤山市东古调味食品有限公司,广东江门529738)摘要:从发酵罐和发酵池中选取发酵过程中的酱油进行中性蛋白酶活力、氨基酸态氮含量、游离氨基酸含量、pH值、总酸含量、有机酸含量、还原糖含量、淀粉酶活力和食盐含量的检测与分析。结果表明:池式发酵酱油的中性蛋白酶活力、氨基酸态氮含量、氨基酸总量、有机酸总量、淀粉酶活力、还原糖含量、总酸含量和pH值都高于罐式发酵酱油;食盐含量则是罐式酱油更多;其中鲜味氨基酸在发酵12d后池式酱油的含量就高于罐式酱油的含量,尤其是池式酱油的谷氨酸在发酵45d时已达到10.42g/kg,而罐式酱油的谷氨酸含量仅7.91g/kg;两种方式发酵的酱油都能检测出7种有机酸,且含量较高的两种有机酸分别是乳酸和乙酸;在发酵结束时池式酱油的还原糖含量比罐式酱油的还原糖含量高1.01g/100g;池式酱油的食盐含量比罐式酱油的食盐含量低0.90g/100g,说明在关键呈味物质上池式发酵酱油优于罐式发酵酱油。关键词:酱油;发酵方式;呈味物质;对比分析文章编号:1673-9078(2023)06-240-245DOI:10.13982/j.mfst.1673-9078.2023.6.0741ComparativeAnalysisoftheKeyFlavoringSubstancesduringtheTank-typeorPool-typeFermentationofSoySauceHUANGLiuyao1,LINLizhao2,WUHuizhen2,SUGuowan1,LINWeifeng1*(1.SchoolofFoodScienceandEngineering,SouthChinaUniversityofTechnology,Guangzhou510640,China)(2.HeshanDongguFlavoringFoodCo.Ltd.,Jiangmen529738,China)Abstract:Theneutralproteaseactivity,aminoacidnitrogencontent,freeaminoacidcontent,pH,totalacidcontent,organicacidcontent,reducingsugarcontent,amylaseactivityandsaltcontentofthesoysaucewithdrawnfromthefermentationtankandfermentationpoolduringfermentationweredeterminedandanalyzed.Theresultsshowedthattheneutralproteaseactivity,aminoacidnitrogencontent,totalaminoacidcontent,totalorganicacidcontent,amylaseactivity,reducingsugarcontent,totalacidcontentandpHofthesoysaucefermentedinthefermentationpoolwerehigherthanthoseofthesoysaucefromthefermentationtank;thesaltcontentofthesoysaucefermentedintankw...