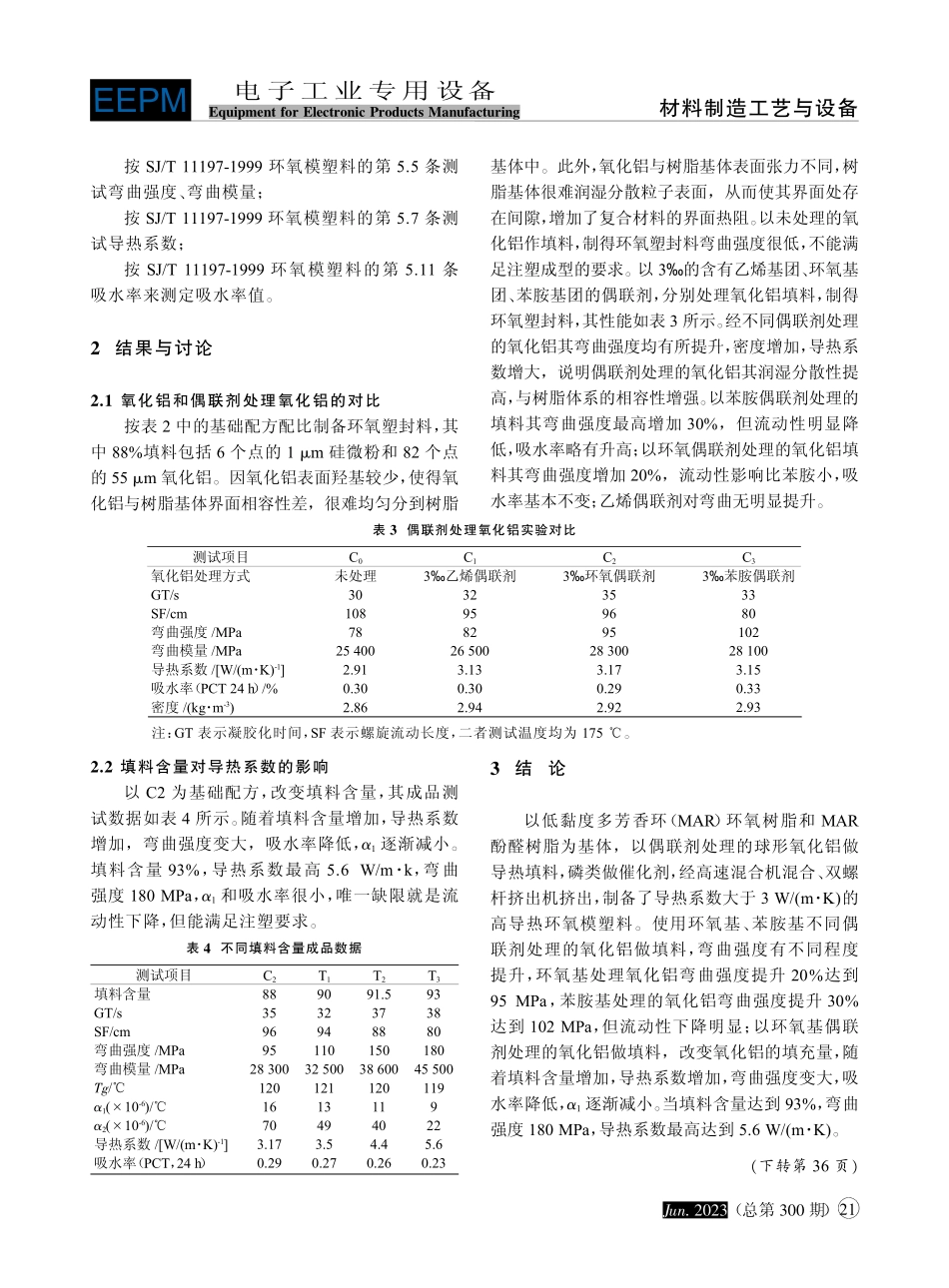

(总第300期)电子工业专用设备EquipmentforElectronicProductsManufacturingEEPMJun.2023收稿日期:2023-04-04高导热环氧模塑料的制备段杨杨,谭伟,李兰侠,刘红杰,范丹丹,刘玲玲,崔亮,蒋小娟(江苏华海诚科新材料股份有限公司,江苏连云港222047)摘要:介绍了导热系数大于3W/(m·K)高导热环氧模塑料的制备。以低黏度多芳香环(MAR)环氧树脂和MAR酚醛树脂为基体,以偶联剂处理的球形氧化铝做导热填料,磷类做催化剂,经高速混合机混合、双螺杆挤出机挤出,合成高导热环氧模塑料。并研究了不同偶联剂类型对弯曲强度的影响。通过改变填充量至93%,导热系数最高可达5.6W/(m·K),且有较好的弯曲性能和流动性能。关键词:高导热;环氧模塑料;氧化铝中图分类号:TN305.94文献标志码:B文章编号:1004-4507(2023)03-0019-04PreparationofEpoxyMoldingCompoundwithHighThermalConductiveDUANYangyang,TANWei,LILanxia,LIUHongjie,FANDandan,LIULingling,CUILiang,JIANGXiaojuan(JiangsuHuahaiChengkeAdvancedMaterialCo.,Ltd.,Lianyungang222047,China)Abstract:Preparationofepoxymoldingcompound(EMC)withthermalconductivegreaterthan3W/(m·K)isintroduced.Usingmulti-aromaticepoxyresinandmulti-aromaticphenolicresinasmatrix,andsphericalaluminatreatedwithcouplingagentisusedasathermalfillerandPhosphorusasacata-lyst,bymeansofhigh-speedpremixureandtwin-screwextruder,thehighthermalconductiveEMCisobtained.Effectsofdifferentcouplingagentonflexuralstrengthareresearchedalso.Inaddition,byadjustingthefillercontentto93%,thethermalconductivecouldbeupto5.6W/(m·K).Meanwhile,EMCremainsgoodfluidityandbendingproperties.Keywords:Highthermalconductive;Epoxymoldingcompound;Aluminumoxide随着封装密度的提高,芯片能耗越来越大,必然要求封装材料具有较高的热导率来满足元器件的散热要求。对于芯片封装材料环氧模塑料(EMC),提高其热导率的方法主要依靠高导热的填料在环氧树脂基体中形成导热链和导热网络[1,2]。最有效的方法就是提高填料的填充率或选择不同类材料制造工艺与设备19(总第300期)电子工业专用设备EquipmentforElectronicProductsManufacturingEEPMJun.2023型、不同粒度的高导热材料进行匹配。传统的EMC,一般选用绝缘性能、抗热震性能良好的硅微粉(熔融型和结晶型SiO2)作填料...