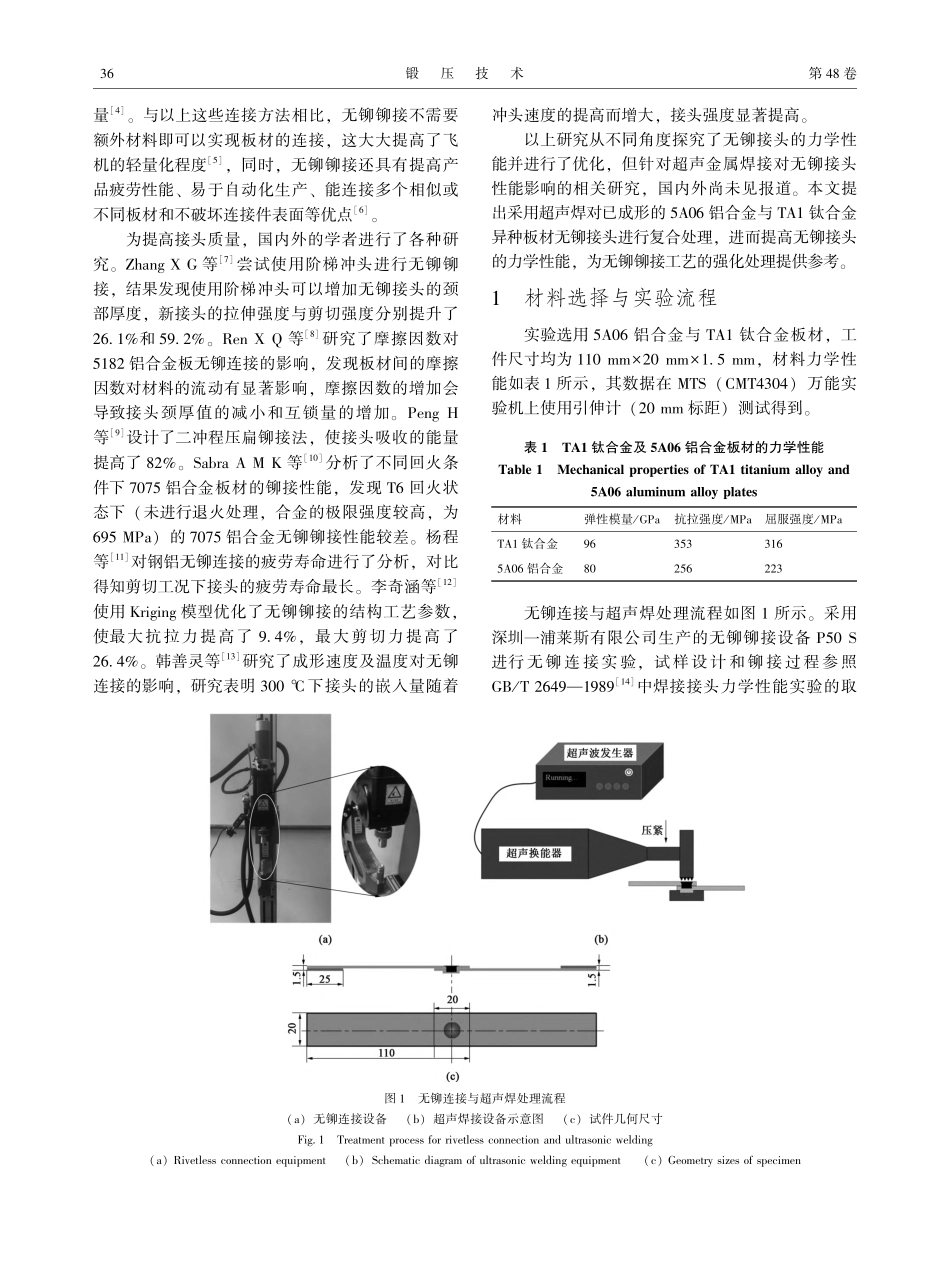

第48卷第6期Vol.48No.6FORGING&STAMPINGTECHNOLOGY2023年6月Jun.2023铝钛异种板材超声无铆接头力学行为及失效机理王世成1,2,李激光1,赵伦2,郭子鑫1,2,霍小乐2,梁召峰2,周光平2,MdShafiqulIslam3(1.辽宁科技大学材料与冶金学院,辽宁鞍山114051;2.深圳职业技术学院智能制造技术研究院,广东深圳518055;3.瑞典布京理工大学工程学院机械工程系,瑞典卡尔斯克鲁纳37179)摘要:为提升无铆接头的静力学性能,采用了一种超声金属焊与无铆连接复合工艺。以5A06铝合金与TA1钛合金为基板,采用无铆连接工艺实现铝钛异种板材的连接并进行超声焊处理,通过拉伸-剪切实验和微观组织观察,探究了超声焊对异种板材无铆接头力学性能的影响。结果表明:超声焊可提升无铆接头的成形质量和静力学性能,尤其铝板为上板时。超声无铆复合工艺强化的根本机制是接头内部存在固相焊,从而使受力形式发生改变,从接头颈部受力变为先焊合区受力。超声焊处理提升了铝合金板的塑性,而钛合金板无明显变化。关键词:超声金属焊;无铆连接;异种合金;力学行为;微观组织DOI:10.13330/j.issn.1000-3940.2023.06.006中图分类号:TH131.1文献标志码:A文章编号:1000-3940(2023)06-0035-08MechanicalbehaviorsandfailuremechanismofultrasonicrivetlessjointforAl-TidissimilarplateWangShicheng1,2,LiJiguang1,ZhaoLun2,GuoZixin1,2,HuoXiaole2,LiangZhaofeng2,ZhouGuangping2,MdShafiqulIslam3(1.FacultyofMaterialsandMetallurgy,UniversityofScienceandTechnologyLiaoning,Anshan114051,China;2.InstituteofIntelligentManufacturingTechnology,ShenzhenPolytechnic,Shenzhen518055,China;3.DepartmentofMechanicalEngineering,FacultyofEngineering,BlekingeInstituteofTechnology,Karlskrona37179,Sweden)Abstract:Toenhancethestaticmechanicalpropertiesofrivetlessjoint,acompositeprocessofultrasonicmetalweldingandrivetlesscon-nectionwasused.Then,taking5A06aluminumandTA1titaniumalloyasthesubstrates,theconnectionofAl-Tidissimilarplateswasconductedbyrivetlessconnection,andtheultrasonicweldingtreatmentwasperformed.Furthermore,theinfluencesofultrasonicweldingonthestaticmechanicalpropertiesofrivetlessjointsforAl-Tidissimilarplateswereexploredbytensile-sheartestandmicrostructureob-servation.Theresultsshowthattheultrasonicweldingcanimprovetheformingqualityan...