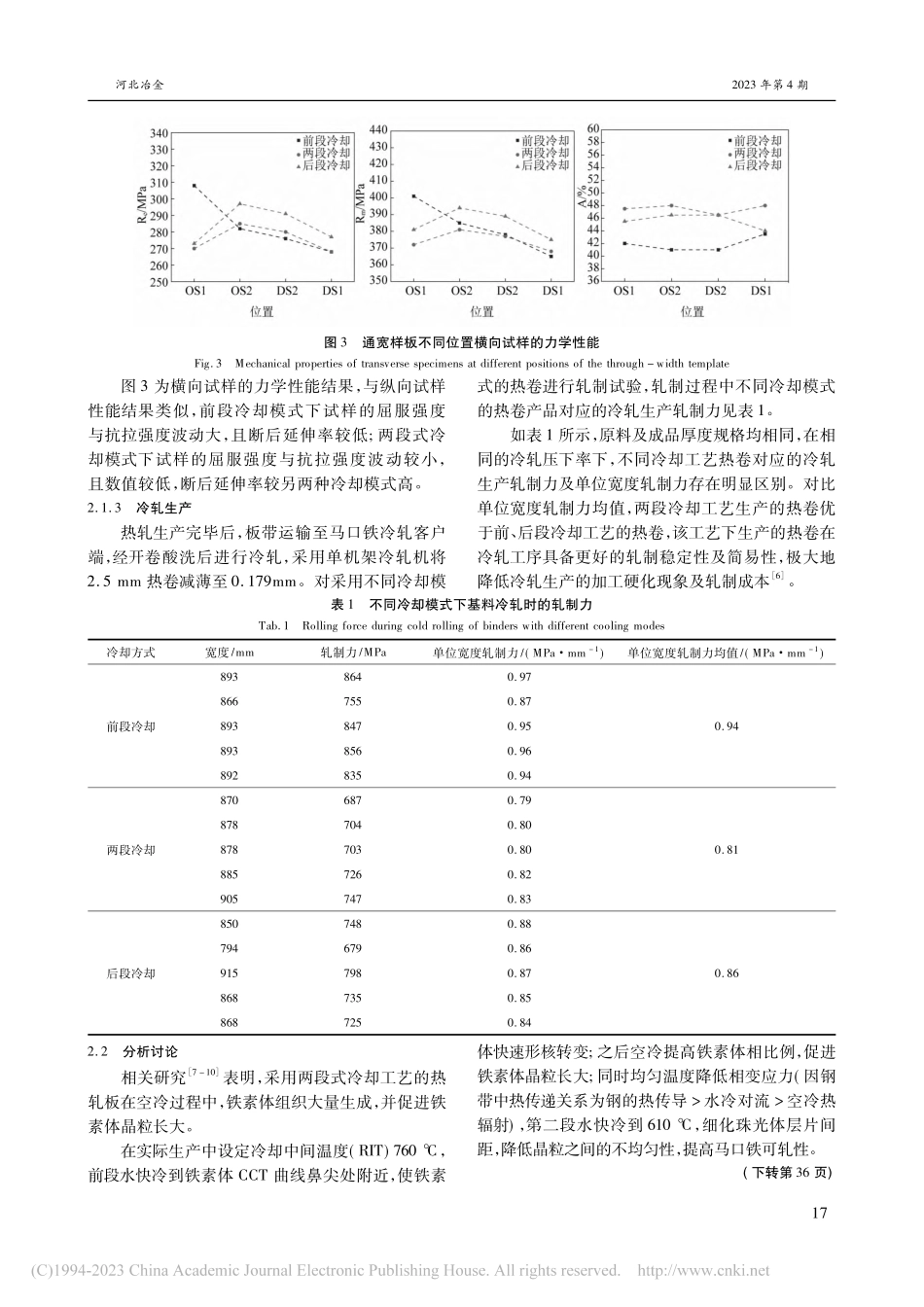

总第328期2023年第4期HEBEIMETALLURGYTotalNo.3282023,Number4冷却模式对马口铁基板MRT-3组织性能的影响郭隆,张征,单庆林,邝霜(河钢集团唐钢公司技术中心,河北唐山063000)摘要:在采用相同热轧温度工艺参数的前提下,对马口铁MRT-3热轧基料采用前段式冷却、两段式冷却、后段式冷却模式进行冷却并完成卷取,分析了不同冷却模式对马口铁热轧组织性能及冷轧生产过程的影响。结果表明,不同冷却工艺下MRT-3热轧板的金相组织均为多边形铁素体,但晶粒尺寸有所差别,采用超快冷-空冷-层流冷的两段式冷却模式的晶粒尺寸较大,平均16.5μm;无论是纵向取样还是横向取样,前段冷却模式下试样不同位置处的抗拉强度和屈服强度波动较大,且极差值较高,断后延伸率低;两段式冷却模式下试样的屈服强度、抗拉强度波动最小,且低于另两种模式,断后延伸率高;后段冷却模式下的力学性能介于两者之间。超快冷-空冷-层流冷的两段式冷却模式可促进铁素体晶粒长大,降低冷轧时的加工硬化,利于冷轧的稳定性。关键词:马口铁;两段式冷却;铁素体;冷轧;热轧基料中图分类号:TG335.1文献标志码:A文章编号:1006-5008(2023)04-0015-03doi:10.13630/j.cnki.13-1172.2023.0403EFFECTOFCOOLINGMODEONMICROSTRUCTUREPROPERTIESOFTINPLATESUBSTRATEMRT-3GuoLong,ZhangZheng,ShanQinglin,KuangShuang(TechnicalCenterofHBISGroupTangsteelCompany,Tangshan063000,Hebei)Abstract:Underthepremiseofusingthesamehotrollingtemperatureprocessparameters,thetinplateMRT-3hot-rolledbasematerialwascooledandwoundbyfront-stagecooling,two-stagecoolingandpost-stagecooling,andtheeffectsofdifferentcoolingmodesonthemicrostructurepropertiesandcoldrollingpro-ductionprocessoftinplatewereanalyzed.TheresultsshowthatthemetallographicstructureofMRT-3hot-rolledplateunderdifferentcoolingprocessesispolygonalferrite,butthegrainsizeisdifferent,andthegrainsizeofthetwo-stagecoolingmodeusingultra-fastcooling-air-cooling-laminarflowcoolingislarger,withanaverageof16.5μm.Whetheritislongitudinalsamplingortransversesampling,thetensilestrengthandyieldstrengthatdifferentpositionsofthespecimeninthefrontcoolingmodefluctuategreatly,andtheextremedifferencevalueishigh,andtheelongationaft...