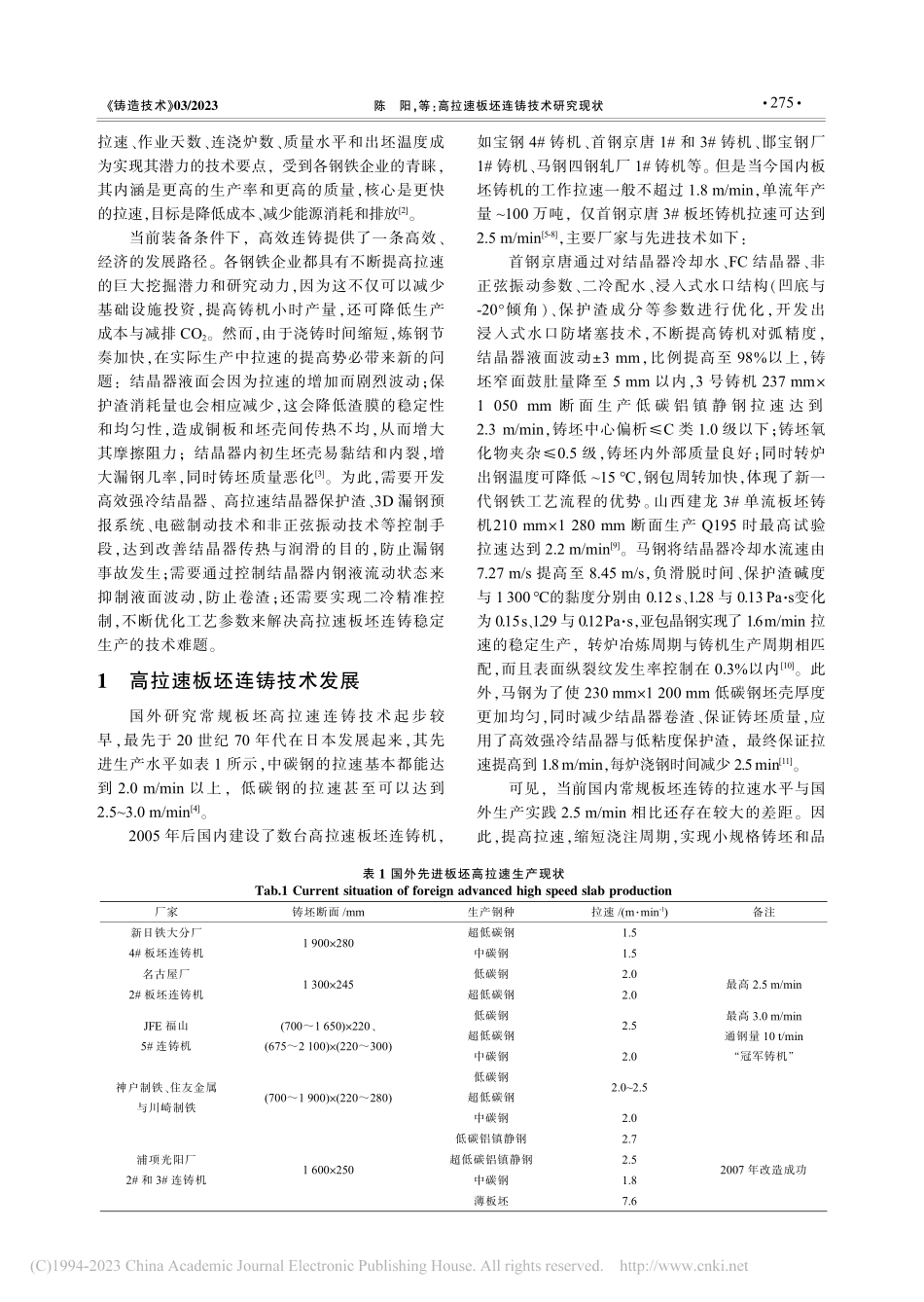

高拉速板坯连铸技术研究现状陈阳1,王芳2,魏民1,张炯明3,李富帅1,陈志凌1,李秀杰1,王学思1(1.中冶南方连铸技术工程有限责任公司,湖北武汉430073;2.武汉工程科技学院人文学院,湖北武汉430200;3.北京科技大学钢铁冶金新技术国家重点实验室,北京100083)摘要:常规板坯铸机浇注窄断面铸坯或生产品种钢时,浇注周期被迫延长,难以实现炉机匹配,严重制约了炼钢车间的生产能力,因此提高连铸机的生产率迫在眉睫,高拉速已成为现代连铸发展的重要方向。本文回顾了国内外高拉速板坯连铸技术发展历程,总结了高拉速连铸的技术特点,重点介绍了高效强冷结晶器、非正弦振动、钢液流动控制、高拉速结晶器保护渣、FC(flowcontrol)结晶器、二冷精准控制等多项关键技术,用于解决高拉速板坯稳定生产的技术难题。高拉速的实现是一项集工艺、装备、生产操作与自动化控制于一体的综合性技术。关键词:高拉速;板坯连铸;FC结晶器;液面波动;二冷精准控制中图分类号:TF777.1文献标识码:A文章编号:1000-8365(2023)03-0274-12ResearchStatusofHighSpeedSlabContinuousCastingTechnologyCHENYang1,WANGFang2,WEIMin1,ZHANGJiongming3,LIFushuai1,CHENZhiling1,LIXiujie1,WANGXuesi1(1.CCTECEngineeringCo.,Ltd.,Wuhan430073,China;2.FacultyofHumanities,WuhanUniversityofEngineeringScience,Wuhan430200,China;3.StateKeyLaboratoryofAdvancedMetallurgy,UniversityofScienceandTechnologyBeijing,Beijing100083,China)Abstract:Whencastingnarrowsectionsorproducinghighqualitysteelgradesbyconventionalslabcaster,thepouringcycleisforcedtobeprolonged,anditisdifficulttoachievematchingofthefurnaceandcaster,whichseriouslyrestrictstheproductioncapacityofsteelmakingworkshops.Therefore,itisurgenttoimprovetheproductivityofcaster,andhighcastingspeedhasbecomeanimportantdevelopmentdirectionofmoderncontinuouscasting.Thispaperreviewsthedevelopmenthistoryofhighspeedslabcontinuouscastingtechnologyathomeandabroad,summarizesthetechnicalcharacteristicsofhighspeedcontinuouscasting,andfocusesonthehighefficiencystrongcoolingmold,nonsinusoidaloscillation,moltensteelflowcontrol,moldpowder,FC(flowcontrol)mold,secondarycoolingprecisioncontrolandotherkeytechnologies,whichareusedtosolvethetechnicalproblemofsta...