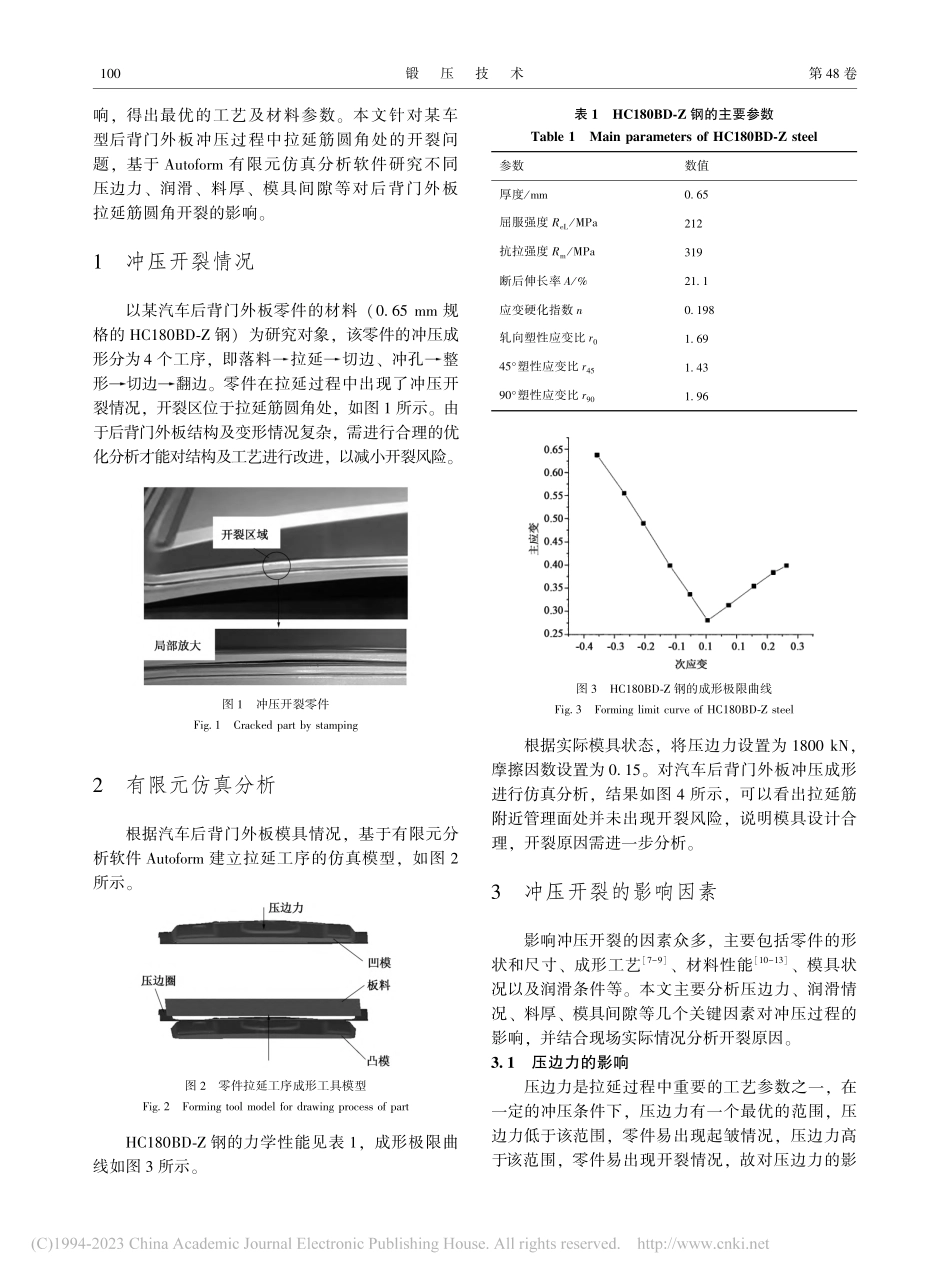

第48卷第3期Vol.48No.3FORGING&STAMPINGTECHNOLOGY2023年3月Mar.2023基于Autoform的后背门外板冲压开裂分析魏绍东1,2,韩龙帅1,2,桑贺1,2,李晓林1,2,陈炜煊1,2,陈洪生3(1.首钢集团有限公司技术研究院,北京100043;2.绿色可循环钢铁流程北京市重点试验室,北京100043;3.首钢京唐钢铁联合有限责任公司制造部,河北唐山063200)摘要:基于冲压成形仿真软件Autoform对某车型后背门外板冲压过程进行模拟仿真,分析了压边力、润滑、料厚及模具间隙等因素对拉延筋圆角减薄率的影响,并基于分析结果解决了拉延筋圆角冲压开裂的问题。结果显示,零件减薄率随着压边力的增加而增加,但拉延筋圆角处减薄率随着压边力的增加而减小,压边力在1400~2000kN之间时,拉延筋圆角处减薄率可保持在19.1%之内;拉延筋圆角处减薄率随着摩擦因数的减小而增加,当摩擦因数为0.11时减薄率达到19.6%;料厚由0.63mm增加至0.67mm时,拉延筋圆角处减薄率由16.0%减小至13.4%;模具间隙对拉延筋圆角开裂的影响最为显著,当模具间隙为0.02mm时,减薄率达到25.5%。故适当提升压边力和摩擦因数、增加料厚、减小模具间隙均可降低拉延筋圆角处减薄率。关键词:冲压;后背门外板;圆角开裂;减薄率;拉延筋DOI:10.13330/j.issn.1000-3940.2023.03.014中图分类号:TG386.3+2文献标志码:A文章编号:1000-3940(2023)03-0099-06StampingcrackanalysisonreardoorouterpanelbasedonAutoformWeiShaodong1,2,HanLongshuai1,2,SangHe1,2,LiXiaolin1,2,ChenWeixuan1,2,ChenHongsheng3(1.TechnicalResearchInstituteofShougangGroupCo.,Ltd.,Beijing100043,China;2.BeijingKeyLaboratoryofGreenandRecyclableSteelProcess,Beijing100043,China;3.ManufacturingDepartmentofShougangJingtangIronandSteelUnitedCo.,Ltd.,Tangshan063200,China)Abstract:BasedonthestampingsimulationsoftwareAutoform,thestampingprocessofreardoorouterpanelforacertainvehiclewassimulated,andtheinfluencesofblankholderforce,lubrication,materialthicknessanddieclearanceonthethinningrateofdrawbeadfil-letwereanalyzed.Then,theproblemofstampingcrackfordrawbeadfilletwassolvedbasedontheanalysisresults.Theresultsshowthatthethinningrateofpartincreaseswiththeincreasingofblankholderforce,butthethinningrateatthedrawbeadfilletdecreaseswiththeincreasingofblankholderforce.Whentheblankholderforceisbetween1400and2000kN,th...