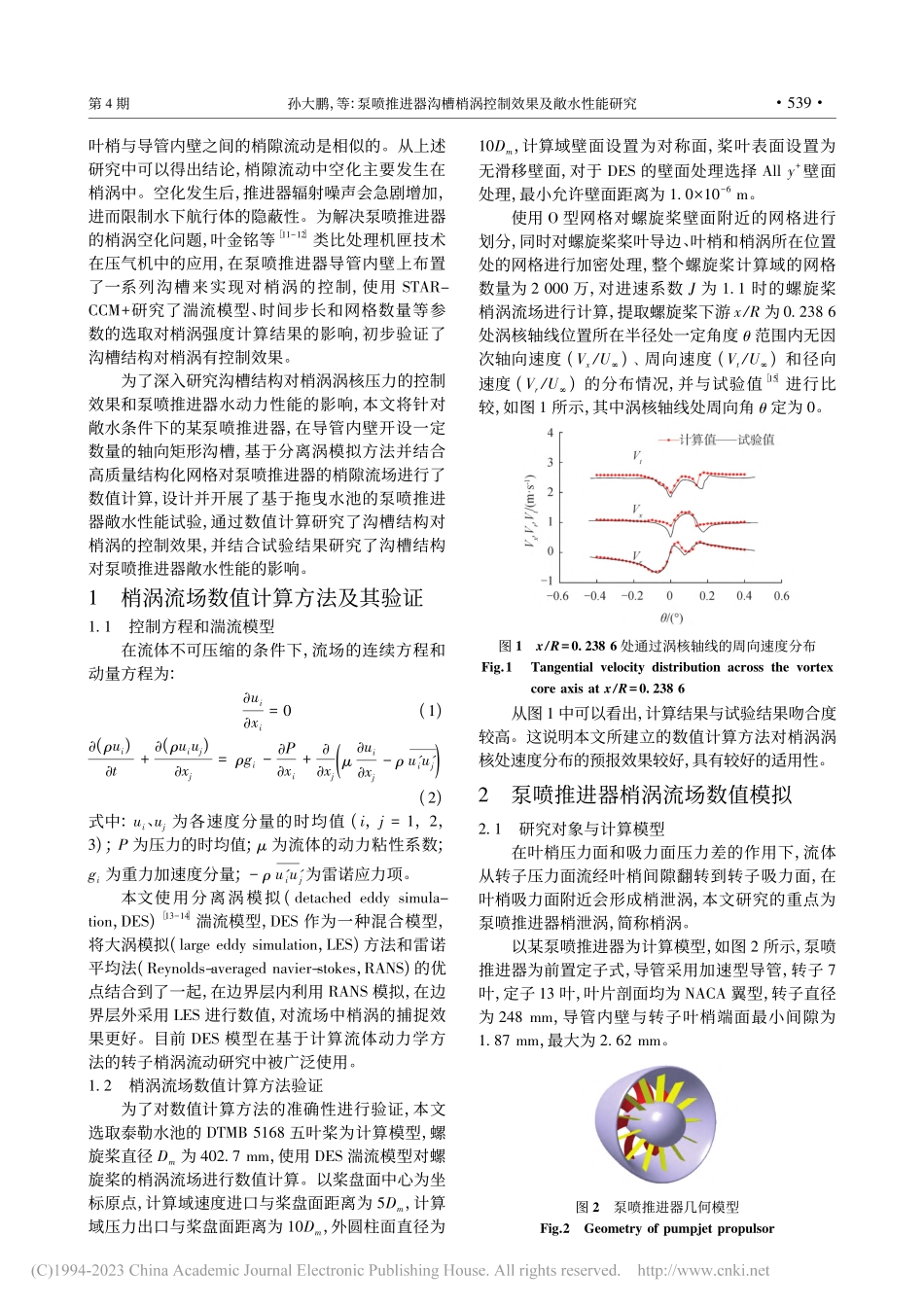

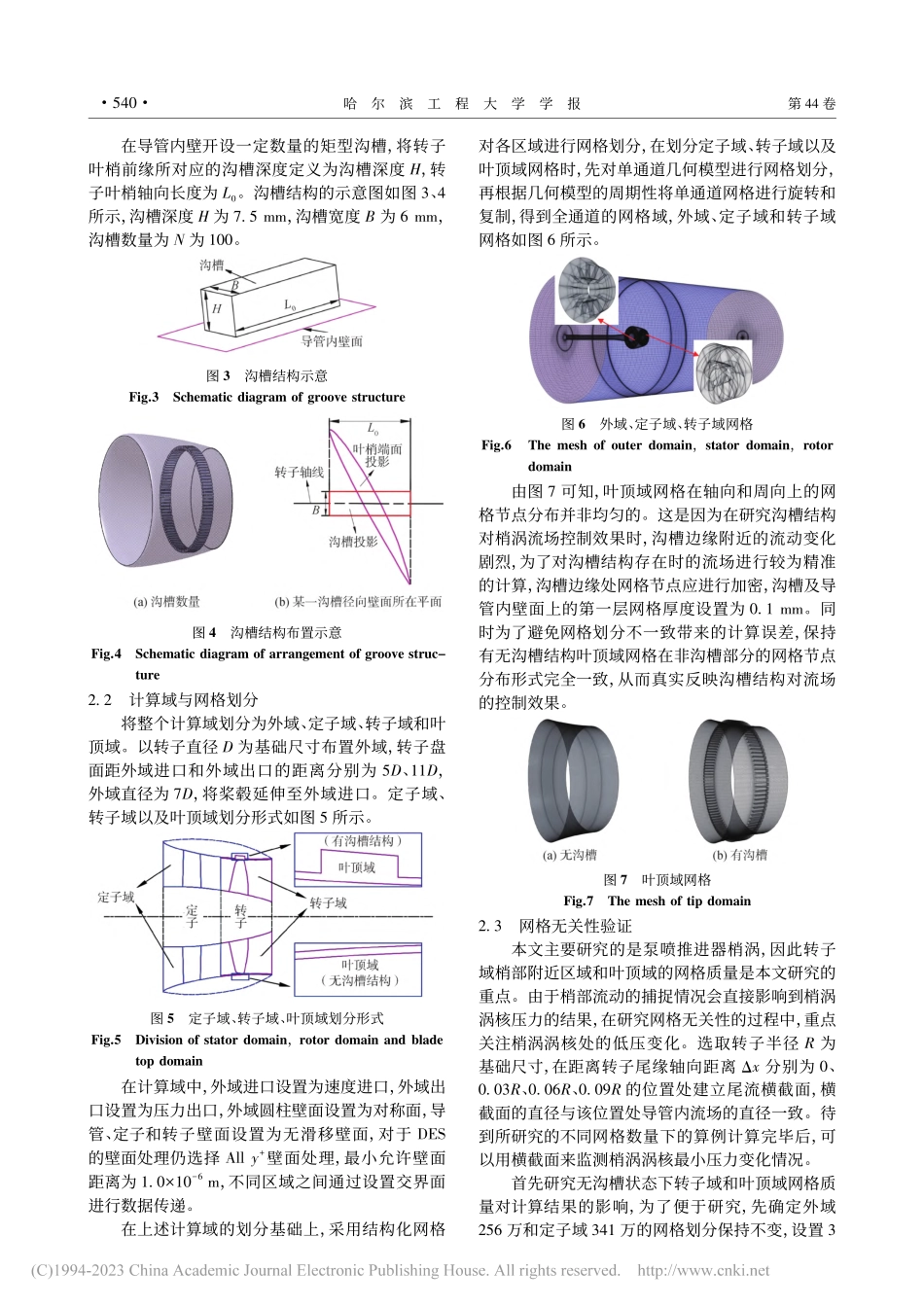

第44卷第4期2023年4月哈尔滨工程大学学报JournalofHarbinEngineeringUniversityVol.44№.4Apr.2023泵喷推进器沟槽梢涡控制效果及敞水性能研究孙大鹏1,叶金铭1,邹笑宇1,吴原润1,史宝雍2(1.海军工程大学舰船与海洋学院,湖北武汉430033;2.91697部队,山东青岛266000)摘要:为控制泵喷推进器梢隙流场,抑制梢涡空化,在导管内壁开设了一定数量的沟槽结构进行研究。本文基于分离涡模拟方法并结合高质量结构化网格对泵喷推进器的梢隙流场进行了数值计算,设计并开展了基于拖曳水池的泵喷推进器敞水性能试验,对比分析了沟槽结构对梢涡形状、梢涡涡核压力和敞水性能的影响。研究表明:沟槽结构可以显著增大梢涡涡核压力,涡核相对压力时均值最少可提高36.57%,在转子尾缘后梢涡低压区域体积可以减少65.8%,能有效延迟梢涡空化,并且对泵喷推进器的水动力性能影响较小,在推进效率上还有一定的改善作用。关键词:泵喷推进器;梢隙流场;沟槽结构;分离涡模拟;结构网格;梢涡;空化;敞水性能DOI:10.11990/jheu.202110057网络出版地址:https://kns.cnki.net/kcms/detail/23.1390.U.20221226.1852.005.html中图分类号:U661.31文献标志码:A文章编号:1006-7043(2023)04-0538-08Tipvortexcontroleffectandopen-waterperformanceofgroovesinapumpjetpropulsorSUNDapeng1,YEJinming1,ZOUXiaoyu1,WUYuanrun1,SHIBaoyong2(1.CollegeofShipandOcean,NavalUniversityofEngineering,Wuhan430033,China;2.No.91697TroopsofPLA,Qingdao266000,China)Abstract:Tocontroltheflowfieldoftipclearanceinapumpjetpropulsorandsuppresstipvortexcavitation,acer-tainnumberofgroovesweresetintheinnerwalloftheductofapumpjetpropulsor.Basedonthedetachededdysimulationmethodandhigh-qualitystructuredgrid,anumericalcalculationofthetipclearanceflowfieldofthepumpjetpropulsorwasperformed,andanopen-waterperformancetestofthepumpjetpropulsorbasedonatowingtankwasdesignedandperformed.Theeffectsofgroovestructureontheshapeofthetipvortex,tipvortexcorepres-sure,andopen-waterperformancewerecomparedandanalyzed.Theresultsshowthatthegroovestructurecansub-stantiallyincreasethecorepressureofthetipvortex,themeanvalueoftherelativepressureofthevortexcorecanbeincreasedbyatleast36.57%,andthevolumeofthelow-pressurer...