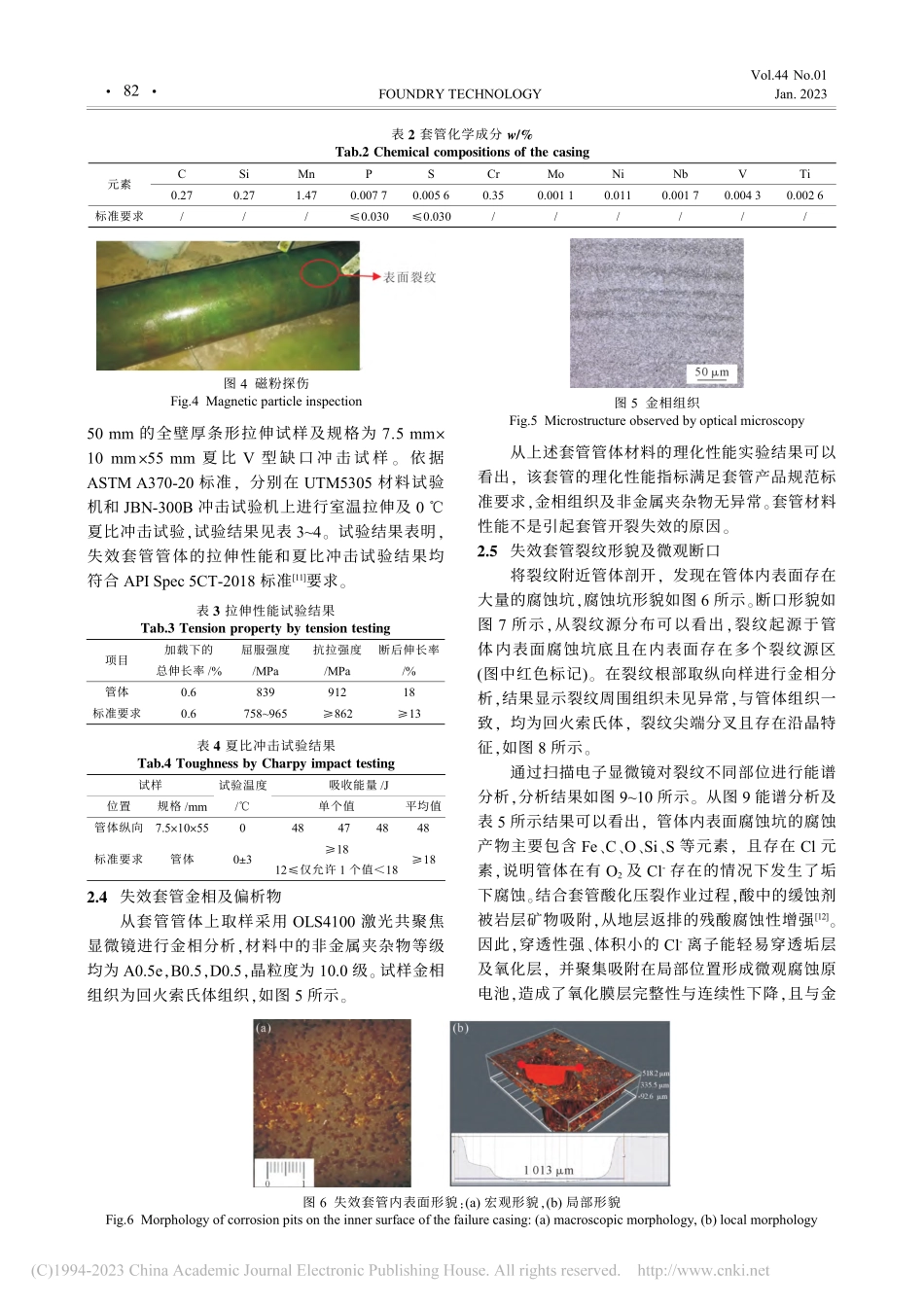

某水平井套管开裂失效实验及数值模拟研究王蕊1,张乐1,闫晓峰2,韩东2,杨鹏1(1.中国石油集团工程材料研究院有限公司,陕西西安710077;2.长庆油田分公司第六采气厂,陕西西安710018)摘要:通过分析水平井套管现场服役工况,并结合宏观观察、理化性能检测、组织分析、扫描电镜观察和能谱分析等实验研究及数值计算方法,系统分析了水平井套管发生开裂失效的原因。结果表明,套管材料性能满足标准要求,但套管内壁存在大量腐蚀坑,套管在酸化压裂过程中发生点蚀。断口分析表明,裂纹起源于腐蚀坑底,套管内部存在非金属夹杂缺陷。通过数值模拟计算,分析了套管在完整及含缺陷状态下的承压能力,套管在腐蚀和缺陷作用下承压能力极大降低。当缺陷深度为0.5mm、内压47MPa时,套管在52MPa压裂过程中沿原始缺陷方向发生开裂失效,与套管在压裂作业过程中失效情况相符。依据所得研究结果提出避免此类失效事故的建议。关键词:水平井套管;腐蚀;缺陷;开裂;有限元模拟中图分类号:TG245;TE982文献标识码:A文章编号:1000-8365(2023)01-0080-06TestandNumericalSimulationResearchofCasingCrackFailureinHorizontalWellsWANGRui1,ZHANGLe1,YANXiaofeng2,HANDong2,YANGPeng1(1.CNPCTubularGoodsResearchInstitute,Xi'an710077,China;2.ChangqingOilfieldBranchNo.6GasProductionPlant,Xi'an710018,China)Abstract:Byanalysingtheworkingconditionsofhorizontalwellcasingsandcombiningexperimentsandnumericalsimulations,suchasmacroscopicobservation,physicalandchemicalpropertytest,microstructureanalysis,SEMandenergyspectrumanalysis,thecausesofcasingcrackingfailureinhorizontalwellsweresystematicallyanalysed.Theresultsshowthatthepropertiesofthecasingmaterialmeettherequirementsofthestandard.However,alotofcorrosionpitsarefoundontheinnerwallofthecasing,andpittingcorrosionoccursinthecasingduringacidfracturing.Thefractureanalysisshowsthatthecrackoriginatesfromthebottomofthecorrosionpit,andtherearenonmetallicinclusionsinthecasing.Throughthenumericalsimulation,thepressurebearingcapacityofthecasingundercompleteanddefectiveconditionsisanalysed,whichisgreatlyreducedundercorrosionanddefects.Whenthedefectdepthis0.5mmandtheinternalpressureis47MPa,thecasingcracksfailalongtheoriginaldefectdirectio...