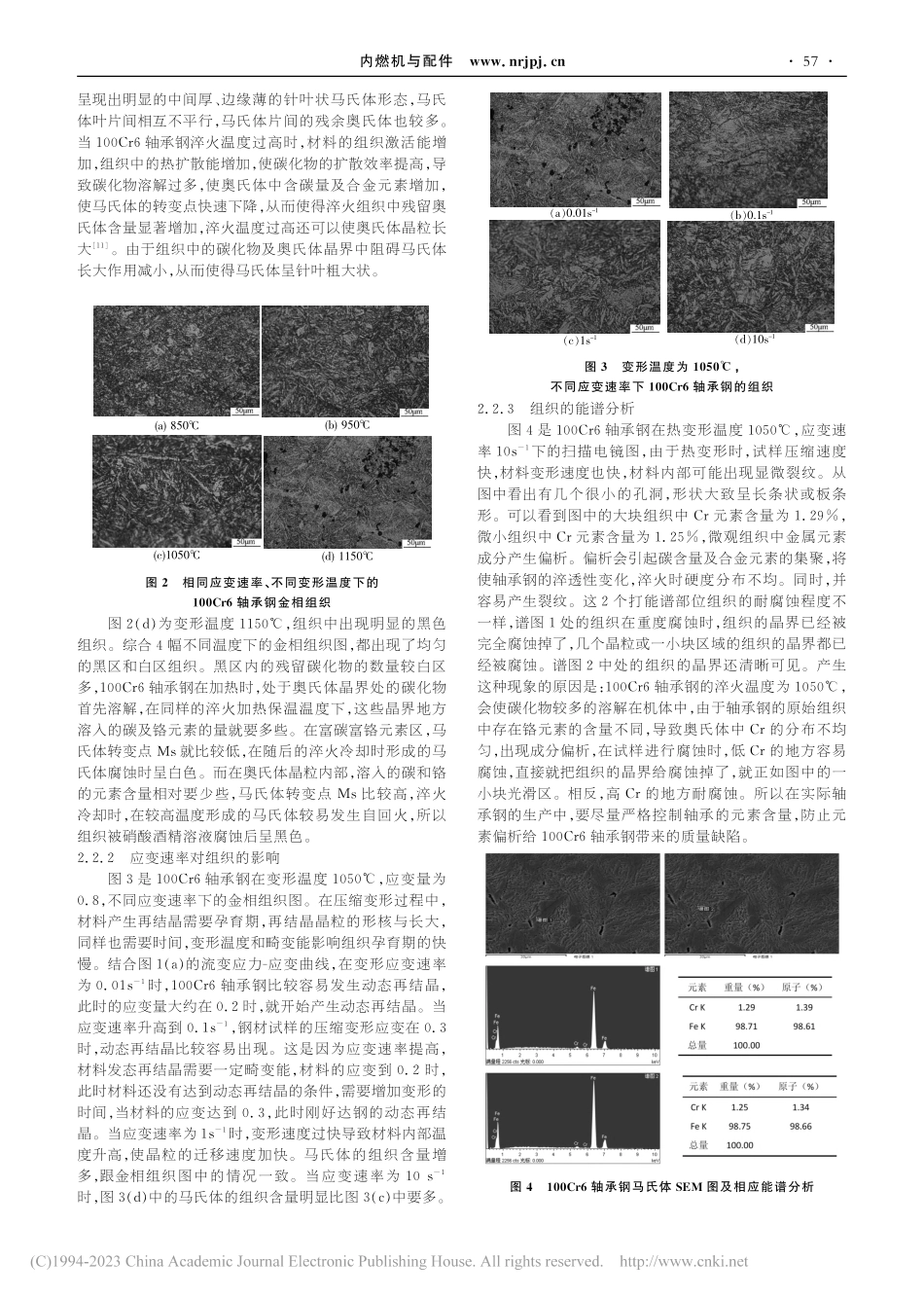

内燃机与配件www.nrjpj.cn100Cr6轴承钢热变形行为及组织研究马帅,陈克飞,何晓庆,李灿(湖南文理学院芙蓉学院,湖南常德415000)摘要:利用Gleeble-3500热模拟试验机研究了100Cr6轴承钢在变形温度为850~1150℃、应变速率为0.01~10s-1条件下的热变形行为。具体分析了应变速率和变形温度对100Cr6轴承钢微观组织的影响,并对组织进行了能谱分析和面扫描分析。结果表明,在相同的应变速率下,流变应力随着温度的升高而降低,马氏体的形态由细晶状长大到针叶粗大状;而在相同的变形温度下,流变应力随着应变速率的升高而增大。当应变速率为0.1s-1时,在850℃和950℃压缩变形时,发生了动态回复软化;而在1050℃和1150℃热压缩变形时,加工硬化的软化机理为动态再结晶。关键词:100Cr6轴承钢;流变应力;组织研究;热压缩变形;动态再结晶中图分类号:TG142文献标识码:A文章编号:1674-957X(2023)05-0055-04StudyofThermalDeformationBehaviorandOrganizationof100Cr6BearingSteelMaShuai,ChenKe-fei,HeXiao-qing,LiCan(HunanUniversityofArtsandSciencesFurongCollege,HunanChangde415000)Abstract:Thethermaldeformationbehaviorof100Cr6bearingsteelatdeformationtemperaturesof850~1150°Candstrainratesof0.01~10s-1wasinvestigatedusingaGleeble-3800thermalsimulationtester.Theeffectsofstrainrateanddeformationtemperatureonthemicrostructureof100Cr6bearingsteelwerespecificallyanalyzed,andtheorganizationwasanalyzedbyenergyspectrumandsurfacescananalysis.Theresultsshowedthatatthesamestrainrate,therheologicalstressdecreasedwiththeincreaseoftemperature,andthemorpholo-gyofmartensitegrewfromfine-grainedtoacicularcoarse;whileatthesamedeformationtemperature,therheo-logicalstressincreasedwiththeincreaseofstrainrate,.Atastrainrateof0.1s-1,dynamicreversionsofteningoccurredat850°Cand950°Ccompressivedeformation,whileat1050°Cand1150°Chotcompressivedeformation,thesofteningmechanismofwork-hardeningwasdynamicrecrystallization.Keywords:100Cr6bearingsteel;Flowstress;OrganizationalResearch;Hotcompressiondeformation;Dy-namicrecrystallization基金项目:湖南省教育厅科学研究基金资助项目(20C1278);湖南文理学院科学研究资助项目(21YB01)作者简介:马帅(1992-),男,湖南岳阳人,硕士,讲师,主要从事金属材料塑性成形及数值模...