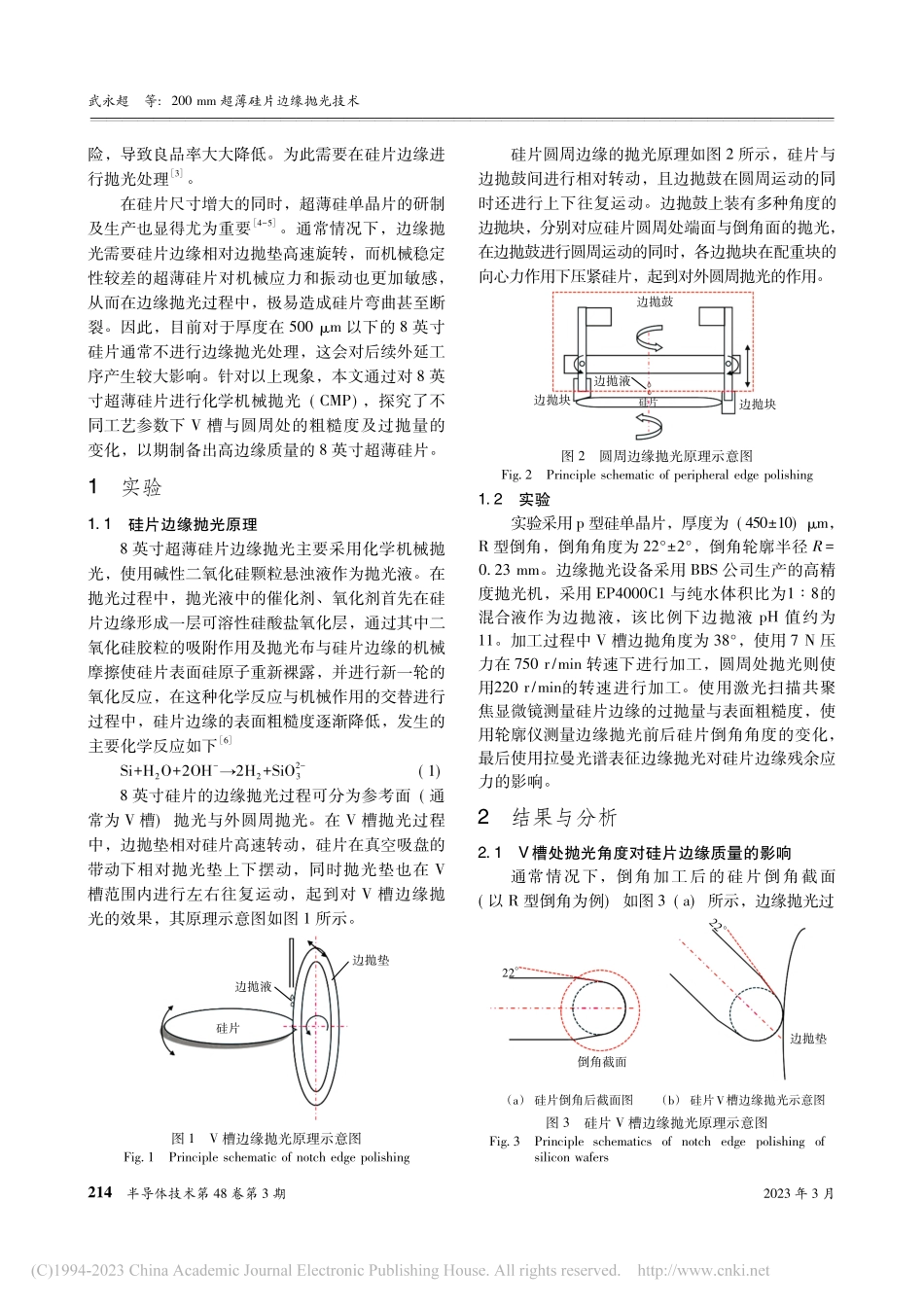

================================DOI:10.13290/j.cnki.bdtjs.2023.03.005March2023SemiconductorTechnologyVol.48No.3213200mm超薄硅片边缘抛光技术武永超,史延爽,王浩铭,龚一夫,张旭,赵权*(中国电子科技集团公司第四十六研究所,天津300220)摘要:在大尺寸硅片外延加工过程中,边缘损伤极易导致外延层位错的产生。厚度为450μm的超薄硅片因其机械强度较低,在边缘抛光过程中极易导致碎片产生。为此采用化学机械抛光(CMP)对8英寸(1英寸=2.54cm)超薄硅片进行边缘抛光,通过优化工艺参数改善硅片边缘粗糙度及过抛量,并讨论了边缘抛光前后硅片倒角角度及边缘残余应力的变化。结果表明边缘抛光工序对硅片边缘去除量较小,且仅对边缘损伤层起到去除作用,因此可以有效降低硅片边缘残余应力,而对倒角角度影响较小,有助于获得边缘质量较好的硅片,为后续外延加工打下良好基础。关键词:边缘抛光;大尺寸超薄硅片;化学机械抛光(CMP);边缘损伤;边缘粗糙度中图分类号:TN305.2文献标识码:A文章编号:1003-353X(2023)03-0213-05EdgePolishingTechnologyfor200mmUltra-ThinSiliconWaferWuYongchao,ShiYanshuang,WangHaoming,GongYifu,ZhangXu,ZhaoQuan*(The46thResearchInstitute,CETC,Tianjin300220,China)Abstract:Duringtheepitaxialprocessingoflarge-sizesiliconwafers,theedgedamagecaneasilyleadtothegenerationofepitaxiallayerdislocations.Theultra-thinsiliconwaferwithathicknessof450μmisveryeasytocausedebrisduringtheedgepolishingprocessduetoitslowmechanicalstrength.Therefore,theedgepolishingof8inch(1inch=2.54cm)ultra-thinsiliconwaferswascarriedoutbychemicalmechanicalpolishing(CMP),andtheedgeroughnessandover-polishingamountofsiliconwaferswerereducedbyoptimizingprocessparameters.Thechangesofthechamferingangleandedgere-sidualstressofsiliconwafersbeforeandafteredgepolishingwerediscussed.Theresultsshowthattheedgepolishingprocesshasasmallerremovalamountontheedgeofthesiliconwafer,andonlyremovestheedgedamagelayer.Itcaneffectivelyreducetheresidualstressontheedgeofsiliconwafers,andhaslittleeffectonthechamferingangle,whichcanhelptoobtainsiliconwaferswithbetteredgequalityandlayagoodfoundationforsubsequentepitaxialprocessing.Keywords:edgepolishing;...