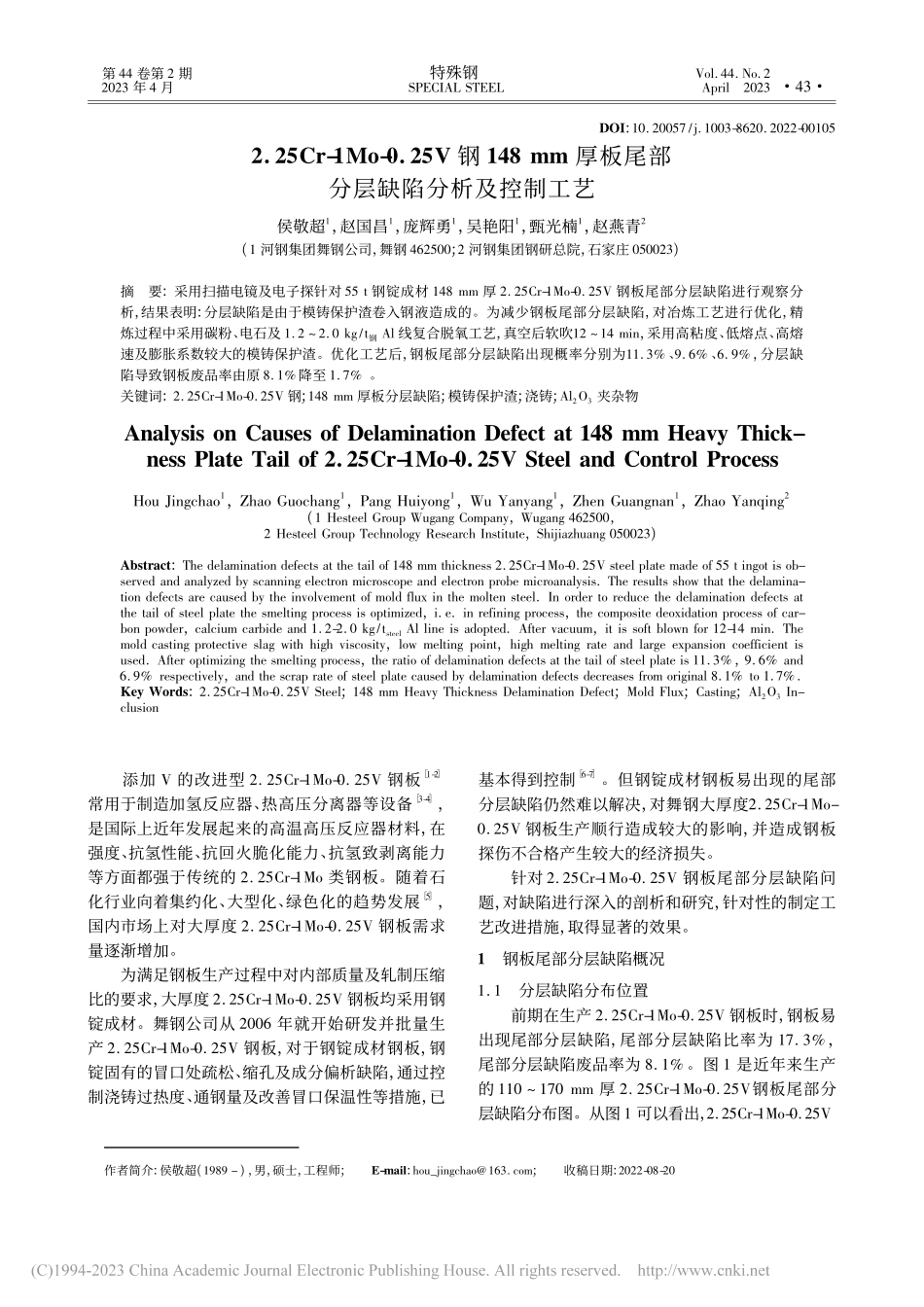

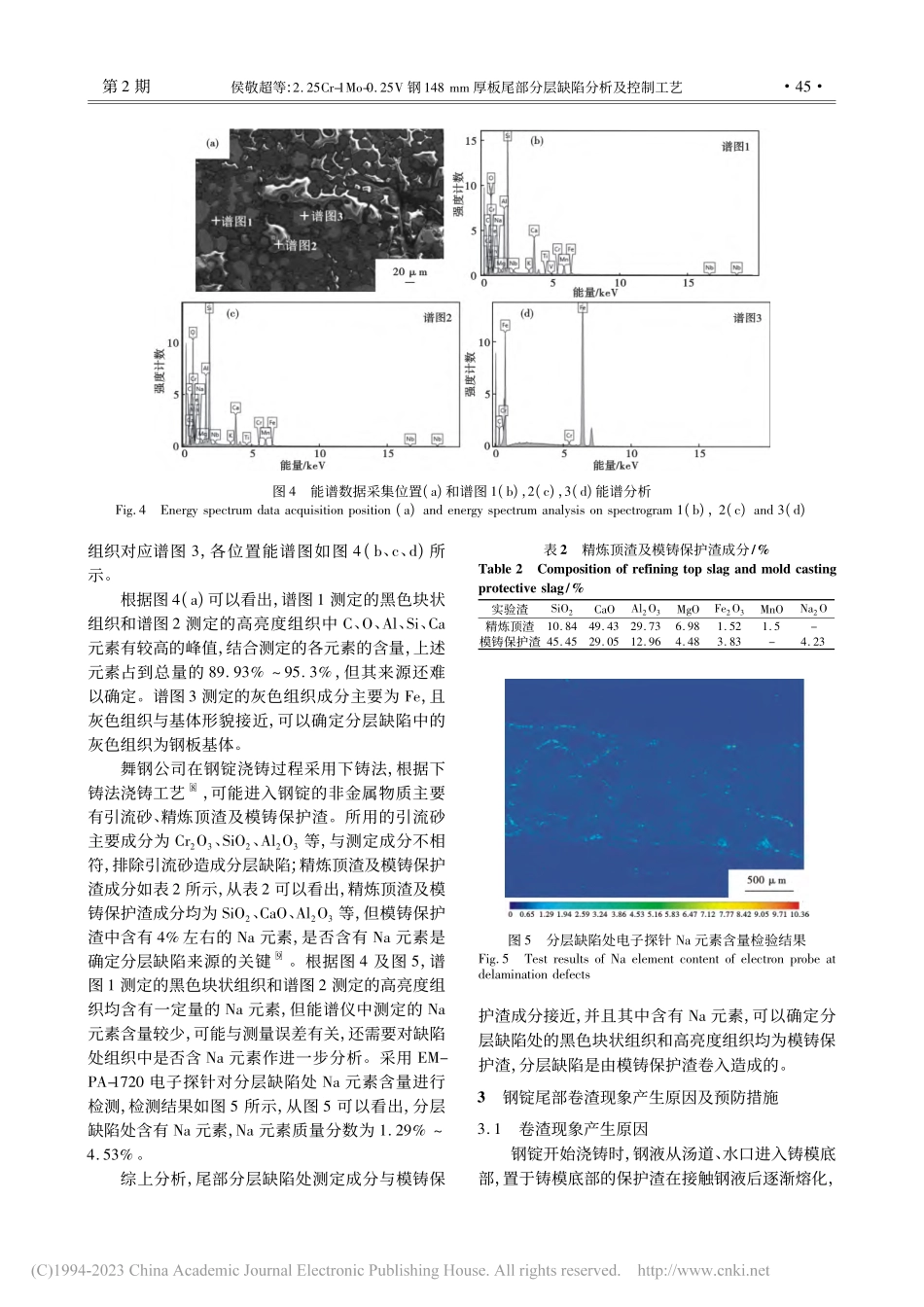

作者简介:侯敬超(1989-),男,硕士,工程师;E-mail:hou_jingchao@163.com;收稿日期:2022-08-20DOI:10.20057/j.1003-8620.2022-001052.25Cr-1Mo-0.25V钢148mm厚板尾部分层缺陷分析及控制工艺侯敬超1,赵国昌1,庞辉勇1,吴艳阳1,甄光楠1,赵燕青2(1河钢集团舞钢公司,舞钢462500;2河钢集团钢研总院,石家庄050023)摘要:采用扫描电镜及电子探针对55t钢锭成材148mm厚2.25Cr-1Mo-0.25V钢板尾部分层缺陷进行观察分析,结果表明:分层缺陷是由于模铸保护渣卷入钢液造成的。为减少钢板尾部分层缺陷,对冶炼工艺进行优化,精炼过程中采用碳粉、电石及1.2~2.0kg/t钢Al线复合脱氧工艺,真空后软吹12~14min,采用高粘度、低熔点、高熔速及膨胀系数较大的模铸保护渣。优化工艺后,钢板尾部分层缺陷出现概率分别为11.3%、9.6%、6.9%,分层缺陷导致钢板废品率由原8.1%降至1.7%。关键词:2.25Cr-1Mo-0.25V钢;148mm厚板分层缺陷;模铸保护渣;浇铸;Al2O3夹杂物AnalysisonCausesofDelaminationDefectat148mmHeavyThick-nessPlateTailof2.25Cr-1Mo-0.25VSteelandControlProcessHouJingchao1,ZhaoGuochang1,PangHuiyong1,WuYanyang1,ZhenGuangnan1,ZhaoYanqing2(1HesteelGroupWugangCompany,Wugang462500,2HesteelGroupTechnologyResearchInstitute,Shijiazhuang050023)Abstract:Thedelaminationdefectsatthetailof148mmthickness2.25Cr-1Mo-0.25Vsteelplatemadeof55tingotisob-servedandanalyzedbyscanningelectronmicroscopeandelectronprobemicroanalysis.Theresultsshowthatthedelamina-tiondefectsarecausedbytheinvolvementofmoldfluxinthemoltensteel.Inordertoreducethedelaminationdefectsatthetailofsteelplatethesmeltingprocessisoptimized,i.e.inrefiningprocess,thecompositedeoxidationprocessofcar-bonpowder,calciumcarbideand1.2-2.0kg/tsteelAllineisadopted.Aftervacuum,itissoftblownfor12-14min.Themoldcastingprotectiveslagwithhighviscosity,lowmeltingpoint,highmeltingrateandlargeexpansioncoefficientisused.Afteroptimizingthesmeltingprocess,theratioofdelaminationdefectsatthetailofsteelplateis11.3%,9.6%and6.9%respectively,andthescraprateofsteelplatecausedbydelaminationdefectsdecreasesfromoriginal8.1%to1.7%.KeyWords:2.25Cr-1Mo-0.25VSteel;148mmHeavyThickne...