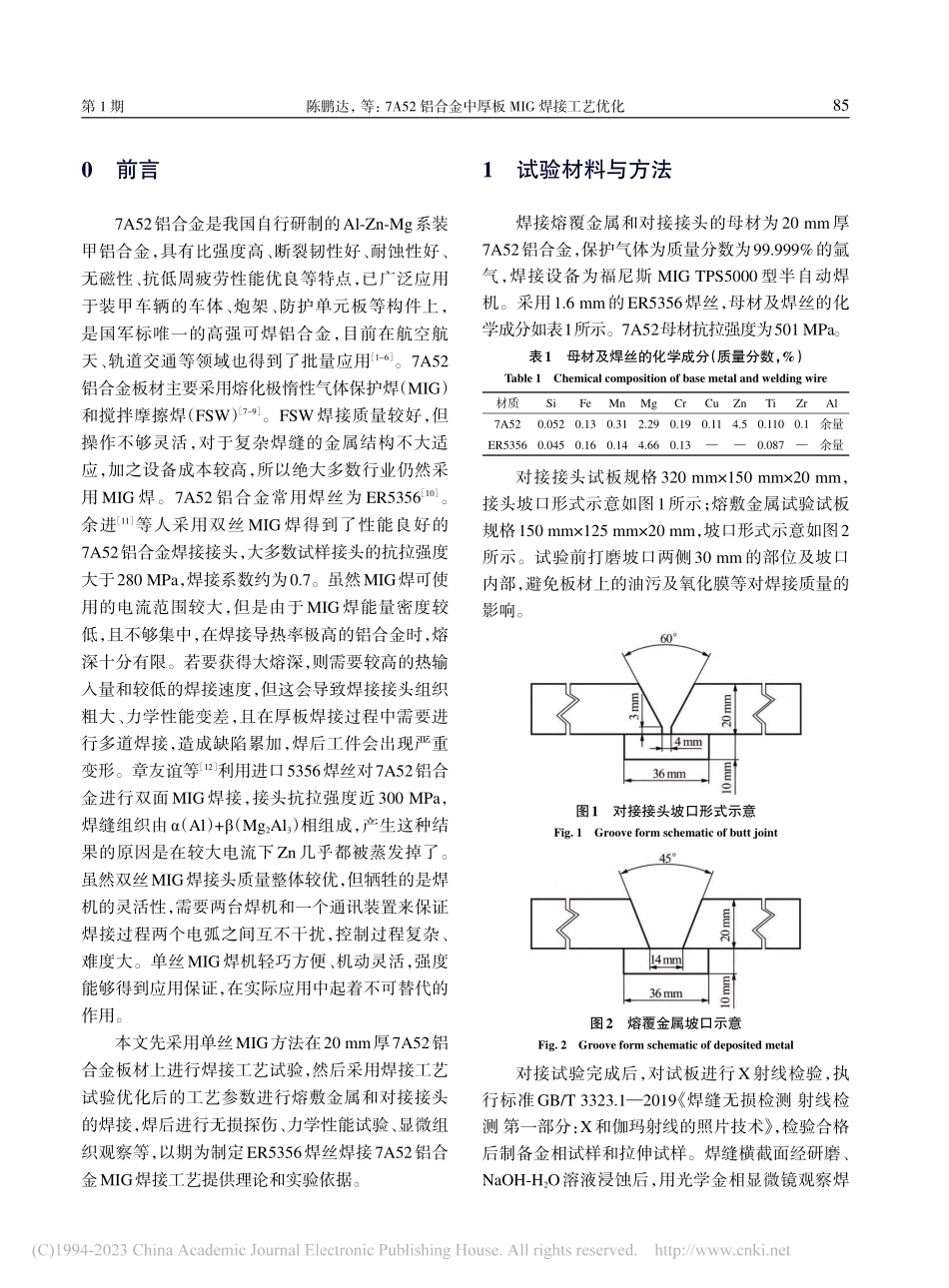

ElectricWeldingMachineVol.53No.1Jan.2023第53卷第1期2023年1月7A52铝合金中厚板MIG焊接工艺优化陈鹏达,徐锴,徐玉君,郭枭,吕晓春哈尔滨焊接研究院有限公司,黑龙江哈尔滨150028摘要:针对7A52铝合金中厚板熔化极惰性气体保护焊(MIG)焊缝成形差、接头系数低等问题,采用半自动MIG、以ER5356焊丝为填充材料对20mm厚7A52铝合金板材进行不同焊接工艺参数下的焊道成形试验。测量不同焊接工艺参数下的焊道熔深、熔宽、余高、润湿角等焊道成形特征,选出最佳工艺参数。采用最佳工艺参数进行20mm厚对接试板的焊接,焊接完成后通过X射线检测、力学性能试验、显微组织观察等测试方法研究对接接头的各项性能。结果表明,ER5356焊丝焊接接头的抗拉强度平均值为302.5MPa,对接接头系数平均值为0.74,试样断裂位置均为焊缝区;接头的弯曲性能良好,未出现裂纹等缺陷;焊接接头焊缝区硬度值最低,为焊接接头最薄弱区域,与拉伸试验试件断裂位置相符合;焊接接头和熔敷金属的力学性能较好。关键词:工艺参数;接头系数;焊道成形;抗拉强度中图分类号:TG457.14文献标识码:A文章编号:1001-2303(2023)01-0084-07OptimizationonMIGWeldingProcessingParametersof7A52AluminumAlloyMedium-ThicknessPlateCHENPengda,XUKai,XUYujun,GUOXiao,LVXiaochunHarbinWeldingInstituteCo.,Ltd.,Harbin150028,ChinaAbstract:Inthispaper,aimingattheproblemsofpoormetalInertgasWelding(MIG)weldformingandlowjointcoeffi‐cientof7A52medium-thicknessplate,taking7A52aluminumalloyastheresearchobject,semi-automaticMIGwasusedtoconductweldbeadformingtestsonER5356wireunderdifferentweldingparameters.Afterthetest,weldbeadformingcharacteristicssuchasweldpenetration,weldwidth,weldbeadremaining-height,weldwettingangleunderdifferentweld‐ingprocessingparametersweremeasured.Optimizetheoptimalprocessingparameters.Theoptimizedprocessparameterswasusedtoweldthedepositedmetalandbuttingjoint.Afterthewelding,throughthetestingmethodsincludeX-raydetec‐tion,mechanicalpropertytest,microstructureobservation,theperformanceofweldingbuttingjointusingER5356wirewasstudied.Theresultsshowthattheaveragetensilestrengthforbuttingjointis302.5MPaandthejointcoefficientis0.74re‐spectively.Thefracturepositionofthebuttingjoint...