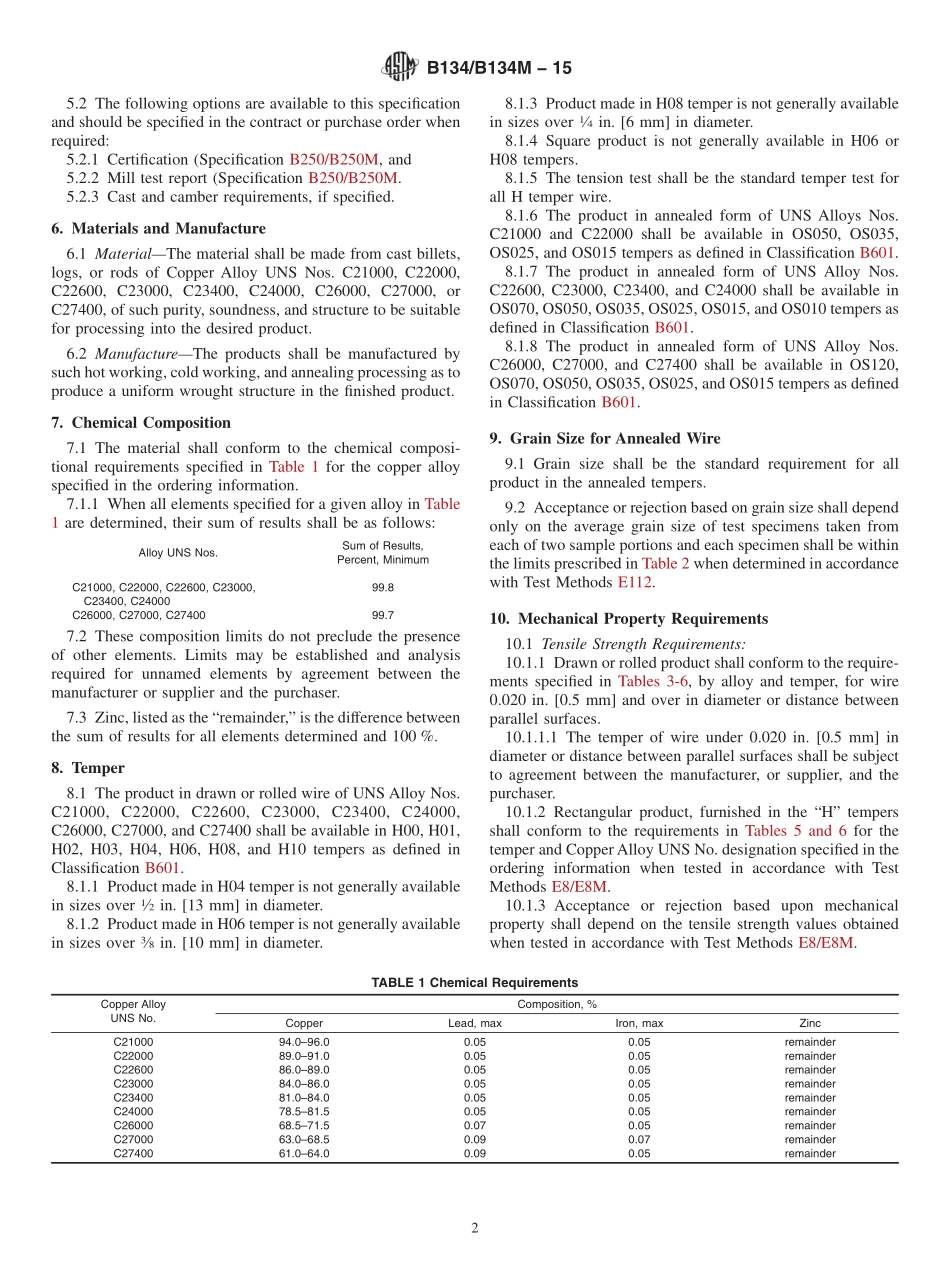

Designation:B134/B134M−15StandardSpecificationforBrassWire1ThisstandardisissuedunderthefixeddesignationB134/B134M;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope*1.1Thisspecificationestablishesrequirementsforround,hexagonal,octagonal,rectangularandsquarebrasswireofUNSAlloyNos.C21000,C22000,C22600,C23000,C23400,C24000,C26000,C27000,andC27400.1.2Units—ThevaluesstatedineitherSIunitsorinch-poundunitsaretoberegardedseparatelyasstandard.Thevaluesstatedineachsystemmaynotbeexactequivalents;therefore,eachsystemshallbeusedindependentlyoftheother.Combiningvaluesfromthetwosystemsmayresultinnon-conformancewiththestandard.2.ReferencedDocuments2.1ASTMStandards:2B250/B250MSpecificationforGeneralRequirementsforWroughtCopperAlloyWireB601ClassificationforTemperDesignationsforCopperandCopperAlloys—WroughtandCastB846TerminologyforCopperandCopperAlloysE8/E8MTestMethodsforTensionTestingofMetallicMa-terialsE112TestMethodsforDeterminingAverageGrainSizeE478TestMethodsforChemicalAnalysisofCopperAlloys3.GeneralRequirements3.1ThefollowingsectionsofSpecificationB250/B250Mconstituteapartofthisspecification.3.1.1Terminology,3.1.2MaterialsandManufacture,3.1.3Workmanship,FinishandAppearance,3.1.4Sampling,3.1.5NumberofTestsandRetests,3.1.6SpecimenPreparation,3.1.7TestMethods,3.1.8SignificanceofNumericallimits,3.1.9Inspection,3.1.10RejectionandRehearing,3.1.11Certification,3.1.12MillTestReports,3.1.13ProductMarking,3.1.14PackagingandPackageMarking,3.1.15SupplementaryRequirements.3.2Inaddition,whenasectionwithatitleidenticaltothatreferencedin3.1appearsinthisspecification,itcontainsadditionalrequirementsthatsupplementthosethatappearinSpecificationB250/B250M.4.Terminology4.1DefinitionsofTermsSpecifictoThisStandard:4.1.1camberoffset,n—theaxialcomponentofcurvatureofwireinanunrestraineds...