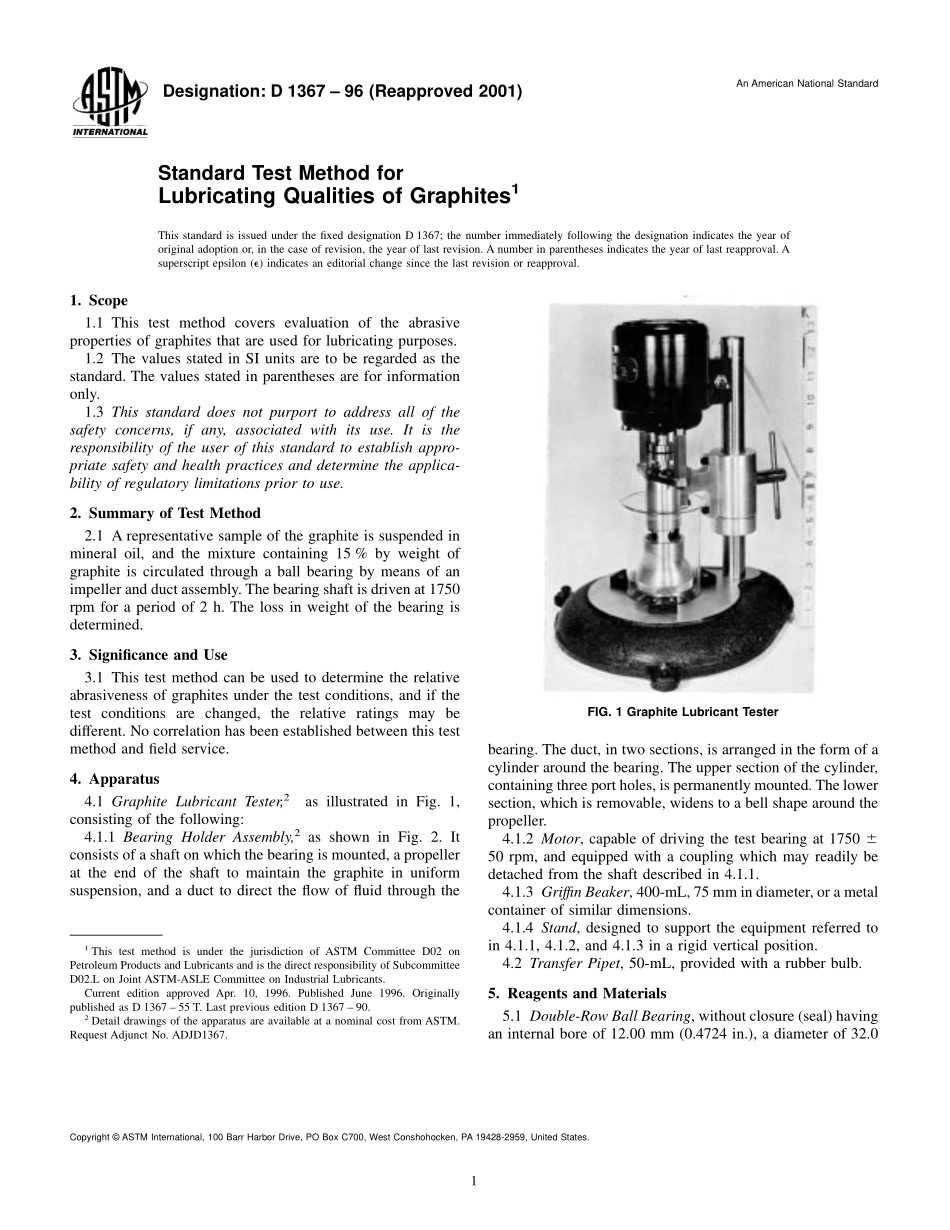

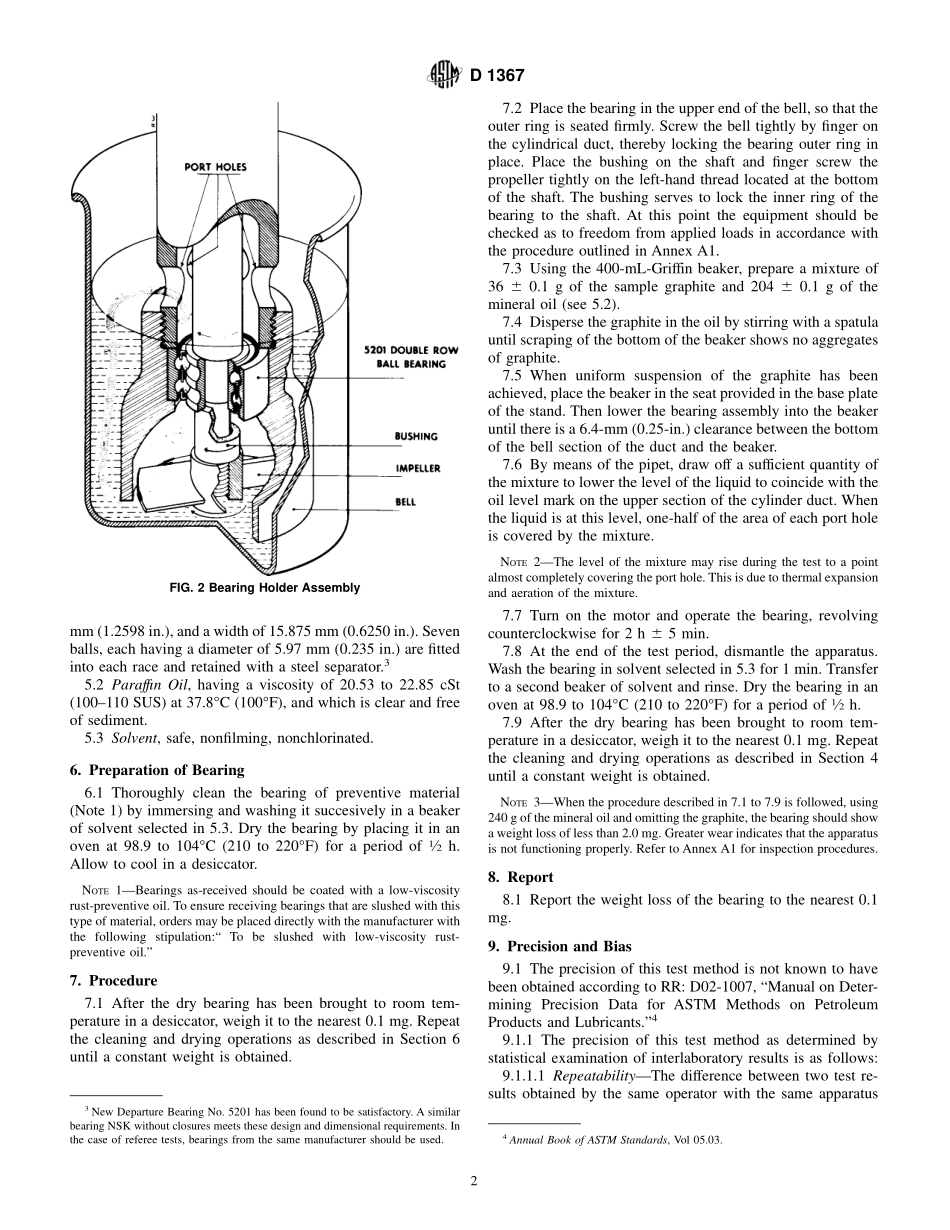

Designation:D1367–96(Reapproved2001)AnAmericanNationalStandardStandardTestMethodforLubricatingQualitiesofGraphites1ThisstandardisissuedunderthefixeddesignationD1367;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(e)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoversevaluationoftheabrasivepropertiesofgraphitesthatareusedforlubricatingpurposes.1.2ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesstatedinparenthesesareforinformationonly.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.SummaryofTestMethod2.1Arepresentativesampleofthegraphiteissuspendedinmineraloil,andthemixturecontaining15%byweightofgraphiteiscirculatedthroughaballbearingbymeansofanimpellerandductassembly.Thebearingshaftisdrivenat1750rpmforaperiodof2h.Thelossinweightofthebearingisdetermined.3.SignificanceandUse3.1Thistestmethodcanbeusedtodeterminetherelativeabrasivenessofgraphitesunderthetestconditions,andifthetestconditionsarechanged,therelativeratingsmaybedifferent.Nocorrelationhasbeenestablishedbetweenthistestmethodandfieldservice.4.Apparatus4.1GraphiteLubricantTester,2asillustratedinFig.1,consistingofthefollowing:4.1.1BearingHolderAssembly,2asshowninFig.2.Itconsistsofashaftonwhichthebearingismounted,apropellerattheendoftheshafttomaintainthegraphiteinuniformsuspension,andaducttodirecttheflowoffluidthroughthebearing.Theduct,intwosections,isarrangedintheformofacylinderaroundthebearing.Theuppersectionofthecylinder,containingthreeportholes,ispermanentlymounted.Thelowersection,whichisremovable,widenstoabellshapearoundthepropeller.4.1.2Motor,capableofdrivingthetestbearingat1750650rpm,andequippedwithacouplingwhichmayre...