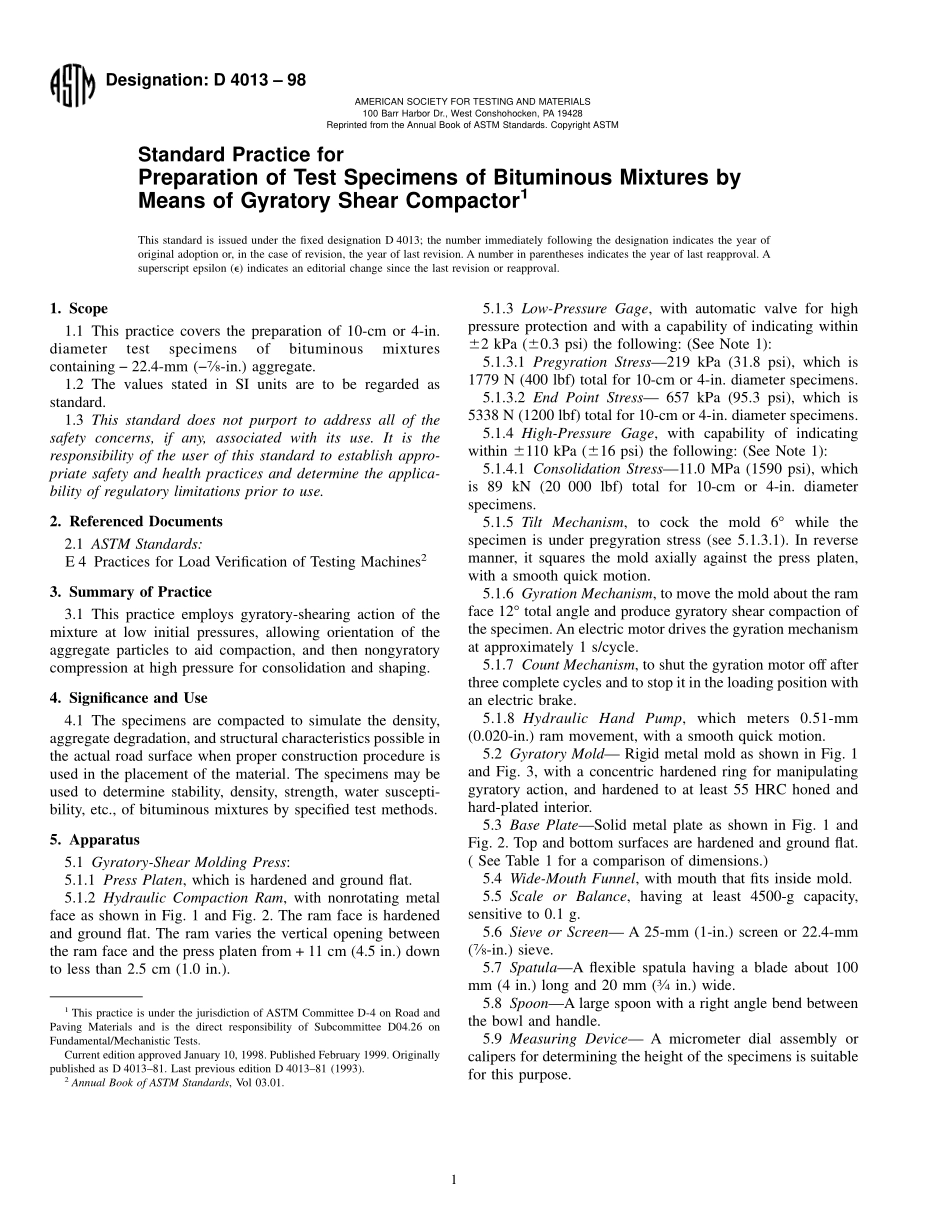

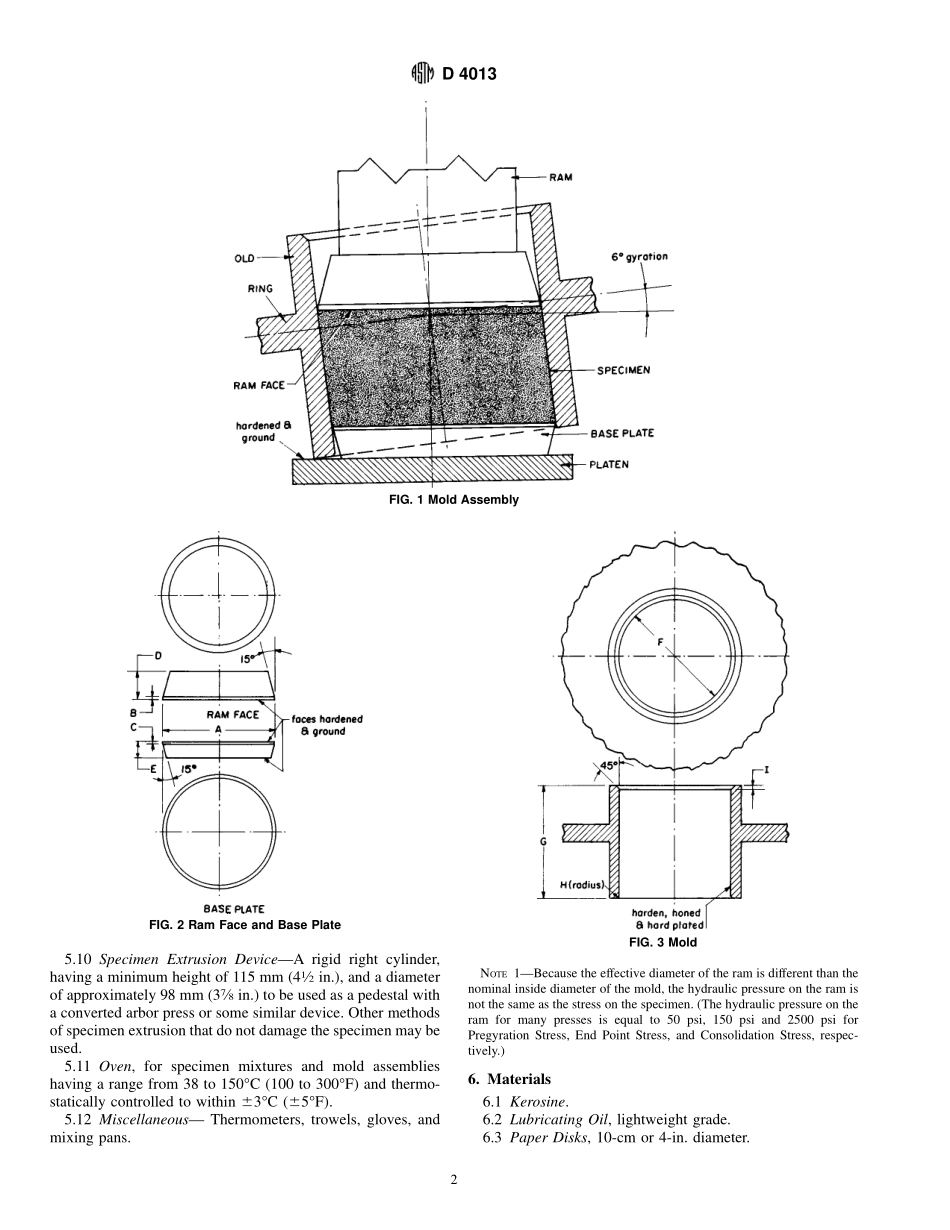

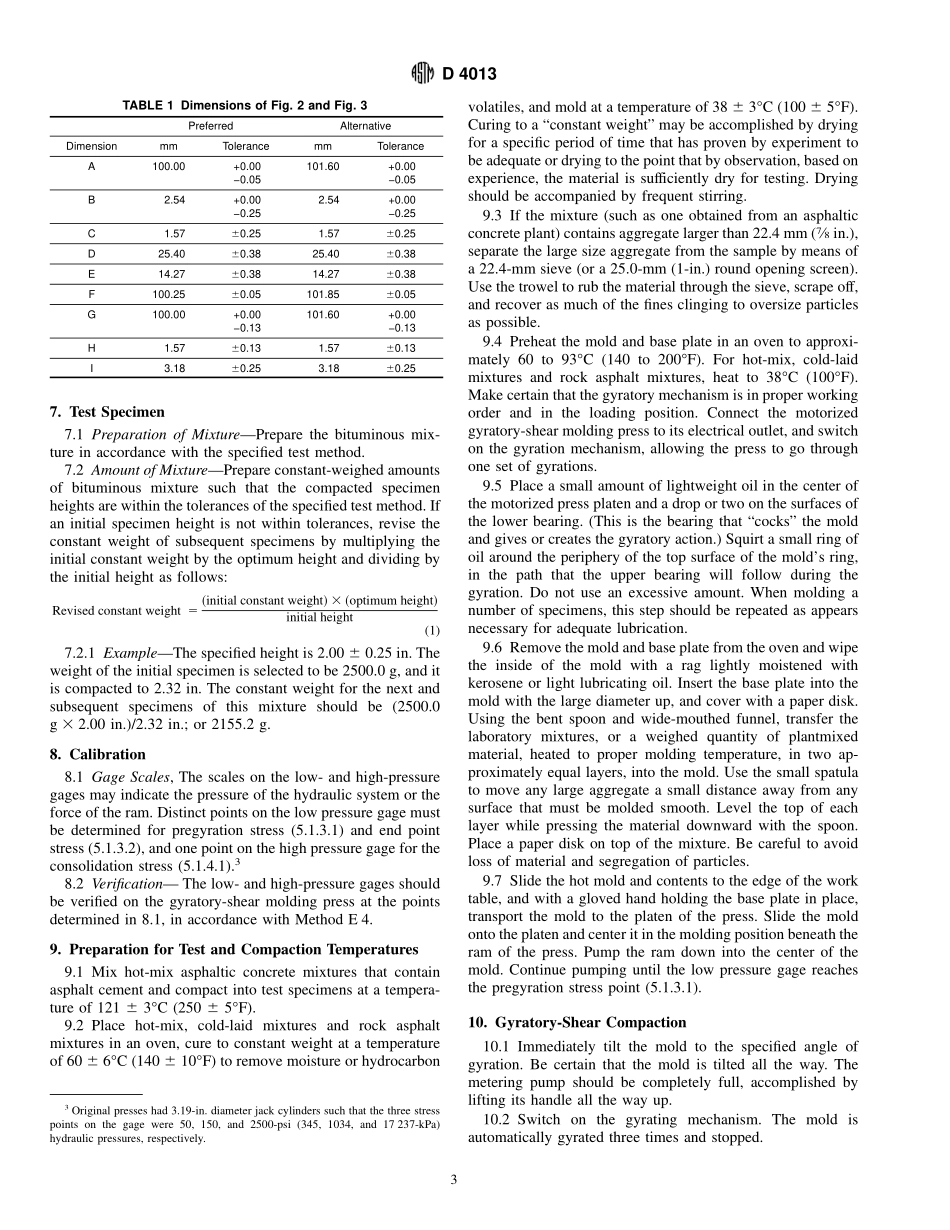

Designation:D4013–98StandardPracticeforPreparationofTestSpecimensofBituminousMixturesbyMeansofGyratoryShearCompactor1ThisstandardisissuedunderthefixeddesignationD4013;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(e)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thispracticecoversthepreparationof10-cmor4-in.diametertestspecimensofbituminousmixturescontaining−22.4-mm(−7⁄8-in.)aggregate.1.2ThevaluesstatedinSIunitsaretoberegardedasstandard.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:E4PracticesforLoadVerificationofTestingMachines23.SummaryofPractice3.1Thispracticeemploysgyratory-shearingactionofthemixtureatlowinitialpressures,allowingorientationoftheaggregateparticlestoaidcompaction,andthennongyratorycompressionathighpressureforconsolidationandshaping.4.SignificanceandUse4.1Thespecimensarecompactedtosimulatethedensity,aggregatedegradation,andstructuralcharacteristicspossibleintheactualroadsurfacewhenproperconstructionprocedureisusedintheplacementofthematerial.Thespecimensmaybeusedtodeterminestability,density,strength,watersuscepti-bility,etc.,ofbituminousmixturesbyspecifiedtestmethods.5.Apparatus5.1Gyratory-ShearMoldingPress:5.1.1PressPlaten,whichishardenedandgroundflat.5.1.2HydraulicCompactionRam,withnonrotatingmetalfaceasshowninFig.1andFig.2.Theramfaceishardenedandgroundflat.Theramvariestheverticalopeningbetweentheramfaceandthepressplatenfrom+11cm(4.5in.)downtolessthan2.5cm(1.0in.).5.1.3Low-PressureGage,withautomaticvalveforhighpressureprotectionandwithacapabilityofindicatingwithin62kPa(60.3psi)thefollowing:(SeeNote1):5.1.3.1PregyrationStress—219kPa(31.8psi),wh...