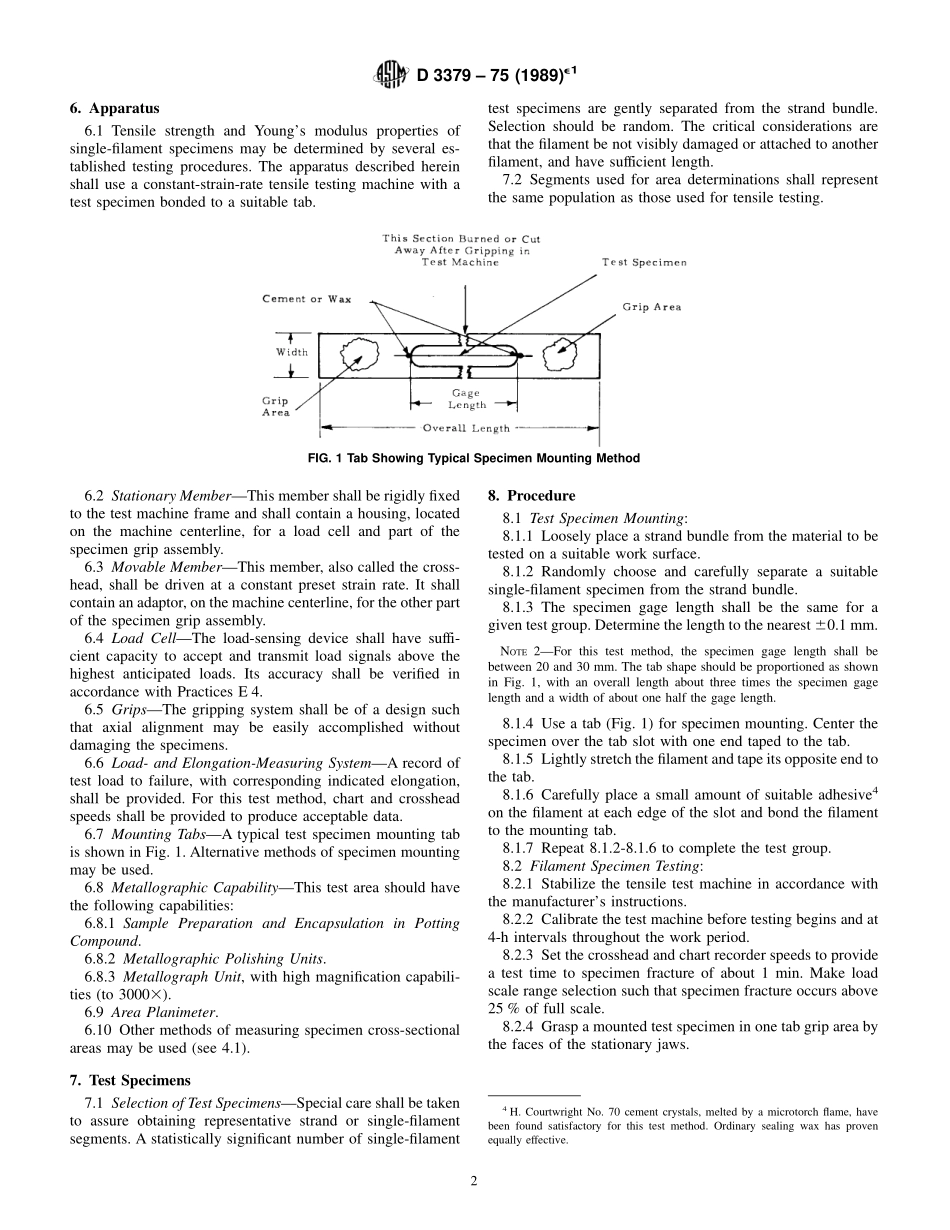

Designation:D3379–75(Reapproved1989)e1StandardTestMethodforTensileStrengthandYoung’sModulusforHigh-ModulusSingle-FilamentMaterials1ThisstandardisissuedunderthefixeddesignationD3379;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(e)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheDepartmentofDefense.e1NOTE—EditorialchangesweremadethroughoutinMay1989.1.Scope1.1Thistestmethodcoversthepreparation,mounting,andtestingofhigh-modulussingle-filamentmaterials[over>213109Pa(>33106psi)]forthedeterminationoftensilestrengthandYoung’smodulus,atroomtemperature.1.2Thistestmethodislimitedtosinglefilamentsutilizingafixedgagelengthatleast2000timeslongerthanthenominalfilamentdiameter.1.3Thisstandardmayinvolvehazardousmaterials,opera-tions,andequipment.Thisstandarddoesnotpurporttoaddressallofthesafetyconcernsassociatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappropriatesafetyandhealthpracticesanddeterminetheapplicabilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:D638TestMethodforTensilePropertiesofPlastics2E4PracticesforForceVerificationofTestingMachines3E6TerminologyRelatingtoMethodsofMechanicalTest-ing33.Terminology3.1Definitions:3.1.1mountingtab—athinpaper,compliantmetal,orplasticstripwithalongitudinalslotoffixedgagelength.Themountingtabshouldbeasthinaspracticabletominimizefilamentmisalignment.3.1.2systemcompliance—thatportionoftheindicatedelongationcontributedbytheloadtrainsystemandthespecimengrippingsystem.Thiscompliancemustbedeter-minedexperimentallyforagivencombinationoftestmachineconditions,gripsystemandmountedspecimen.Itmustbesubtractedfromtheindicatedelongationtoyieldtruespecimenelongationinthegagelength(Note1).Systemcompliancecorrectionwillnotapplywhenelongationinthespecimengagelengthisdeterminedbydirectmeasuremen...