This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D3280 − 85 (Reapproved 2020)

Standard Test Methods for

Analysis of White Zinc Pigments1

This standard is issued under the fixed designation D3280; the number immediately following the designation indicates the year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (ε) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 These test methods cover procedures for the analysis of white zinc pigments.

1.2 The analytical procedures appear in the following order:

Section

Total Zinc, Using Diphenylamine as Internal Indicator 7

Total Zinc, Using Uranyl Acetate as External Indicator 8

Moisture and Other Volatile Matter 11

Moisture and Other Volatile Matter 16

Moisture and Other Volatile Matter 21

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appro- priate safety, health, and environmental practices and deter- mine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accor- dance with internationally recognized principles on standard- ization established in the Decision on Principles for the Development of International Standards, Guides and Recom- mendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

![]()

1 These test methods are under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications and are the direct responsibility of Subcommittee D01.31 on Pigment Specifications.

Current edition approved June 1, 2020. Published July 2020. Originally approved in 1973. Last previous edition approved in 2014 as D3280 – 85 (2014). DOI: 10.1520/D3280-85R20.

2. Referenced Documents

2.1 ASTM Standards:2

D280 Test Methods for Hygroscopic Moisture (and Other Matter Volatile Under the Test Conditions) in Pigments

D1193 Specification for Reagent Water

D1394 Test Methods for Chemical Analysis of White Tita- nium Pigments

E11 Specification for Woven Wire Test Sieve Cloth and Test Sieves

3. Summary of Test Method

3.1 Zinc Oxide:

3.1.1 Total Zinc—Determined using diphenylamine as an internal indicator and also using uranyl acetate as an external indicator. Total impurities are calculated.

3.1.2 Total Sulfur—Determined as BaSO4 and calculated to sulfur.

3.1.3 Moisture and Volatile Matter—Determined in accor- dance with Method A of Test Methods D280.

3.2 Leaded Zinc Oxide:

3.2.1 Total Lead—Determined as PbSO4 and calculated to percent PbO.

3.2.2 Total Zinc—Determined on the filtrate from procedure in 13.2.1 in accordance with methods in Sections 7 or 8.

3.2.3 Total Sulfur—Determined as BaSO4 and calculated to percent SO3.

3.2.4 Total Impurities—Calculated from compositional data.

3.2.5 Moisture and Other Volatile Matter—Determined in accordance with Method A of Test Methods D280.

3.2.6 Water Soluble Salts—Determined gravimetrically.

3.3 Zinc Sulfide:

3.3.1 Total Zinc—Determined using uranyl acetate external indicator in accordance with Section 9.

3.3.2 Zinc Sulfide—Determined in accordance with Sections

8 or 9 and calculating ZnO to ZnS.

3.3.3 Water Soluble Salts—Determined in accordance with Section 18.

![]()

2 For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

![]() D3280 − 85 (2020)

D3280 − 85 (2020)

3.3.4 Moisture—Determined in accordance with Method A of Test Methods D280.

3.3.5 Barium Sulfate—The sample is treated with N2SO4 and Na2CO3 and the residue of BaCO3 is dissolved in NCl and (NH4)2SO4 added to precipitate BaSO4, which is weighed.

3.3.6 Titanium Dioxide—Determined in accordance with Test Methods D1394.

4. Significance and Use

4.1 White zinc pigments find considerable use in white paints, and as such it is useful to formulators and users to be able to monitor the amounts of these pigments in whole paints. It is also of interest to raw material suppliers and paint producers to check the specifications of each pigment.

5. Reagents

5.1 Purity of Reagents—Reagent grade chemicals shall be used in all tests. Unless otherwise indicated, it is intended that all reagents shall conform to the specifications of the Commit- tee on Analytical Reagents of the American Chemical Society, where such specifications are available.3 Other grades may be used, provided it is first ascertained that the reagent is of sufficiently high purity to permit its use without lessening the accuracy of the determination.

5.2 Purity of Water—Unless otherwise indicated, references to water shall be understood to mean Type II reagent grade water conforming to Specification D1193.

5.3 Concentration of Reagents:

5.3.1 Concentrated Acids and Ammonium Hydroxide— When acids and ammonium hydroxide are specified by name or chemical formula only it should be understood that concen- trated reagents of the following specific gravities or concen- trations are intended:

|

Acetic acid, HC2H3O2 Hydrochloric acid, HCl Hydrofluoric acid, HF Nitric acid, HNO3 Sulfuric acid, H2SO4 Ammonium hydroxide, NH4OH |

99.5 % sp gr 1.19 48 % sp gr 1.42 sp gr 1.84 sp gr 0.90 |

The desired specific gravities or concentrations of all other concentrated acids are stated whenever they are specified.

5.3.2 Diluted Acids and Ammonium Hydroxide— Concentrations of diluted acids and ammonium hydroxide, except when standardized, are specified as a ratio stating the number of volumes of the concentrated reagents to be diluted with a given number of volumes of water, as in the following example: HCl (1+99) means 1 volume of concentrated HCl (sp gr 1.19) diluted with 99 volumes of water.

6. Preparation of Sample

6.1 Grind dry pigments, if lumpy or not finely ground, to a fine powder for analysis. Large samples may be thoroughly

![]()

3 ACS Reagent Chemicals, Specifications and Procedures for Reagents and Standard-Grade Reference Materials, American Chemical Society, Washington, DC. For suggestions on the testing of reagents not listed by the American Chemical Society, see Analar Standards for Laboratory Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia and National Formulary, U.S. Pharma- copeial Convention, Inc. (USPC), Rockville, MD.

mixed and a representative portion taken and powdered if lumpy or not finely ground. Mix the sample in all cases thoroughly before taking specimens for analysis.

6.2 Separate pigments from paints or pastes, grind to a fine powder, pass through a 180-µm (No. 80) sieve (Note 1) to remove any skins, thoroughly mix, and oven dry at 105°C. Moisten such pigments after weighing with a little alcohol before adding reagents for analysis.

NOTE 1—Detailed requirements for this sieve are given in Specification E11.

6.3 Preserve all samples in stoppered bottles or containers. ZINC OXIDE

7. Total Zinc, Using Diphenylamine as Internal Indicator

7.1 Reagents:

7.1.1 Diphenylamine Indicator Solution (10 g/L))— Dissolve 1 g of diphenylamine in 100 mL of H2SO4.

7.1.2 Potassium Ferrocyanide (1 mL = 0.008 g Zn)— Dissolve 35 g of K4Fe(CN)6·3H2O in water and dilute to 1 L and add 0.3 g of potassium ferricyanide (K3Fe(CN)6). Stan- dardize the solution by titrating against zinc (320 to 340 mg), following the procedure described in 7.2. Calculate the grams of zinc equivalent to 1.00 mL of the solution.

7.2 Procedure—Weigh to 0.1 mg about 0.4 g of the sample into a tall form 400-mL beaker. Moisten with about 20 mL of water, and dissolve in 15 mL of HCl. Neutralize with NH4OH, using litmus as the indicator. Add an excess of 15 mL of H2SO4 (1+2) and dilute to 200 mL. Heat to approximately 60°C, add 2 drops of diphenylamine indicator solution and while stirring vigorously, titrate with K4Fe(CN)6 solution to the color change from purple to a persistent yellowish green.

NOTE 2—The true end point is a sharp, persistent change from a purple to a yellowish green. At the beginning of the titration, a deep blue color is developed after addition of a few millilitres of K4Fe(CN)6 solution. About 0.5 to 1.0 mL before the true end point is reached, the solution changes from a blue to a purple color. After the purple color is developed, the titration should be continued dropwise to the persistent yellowish green end point.

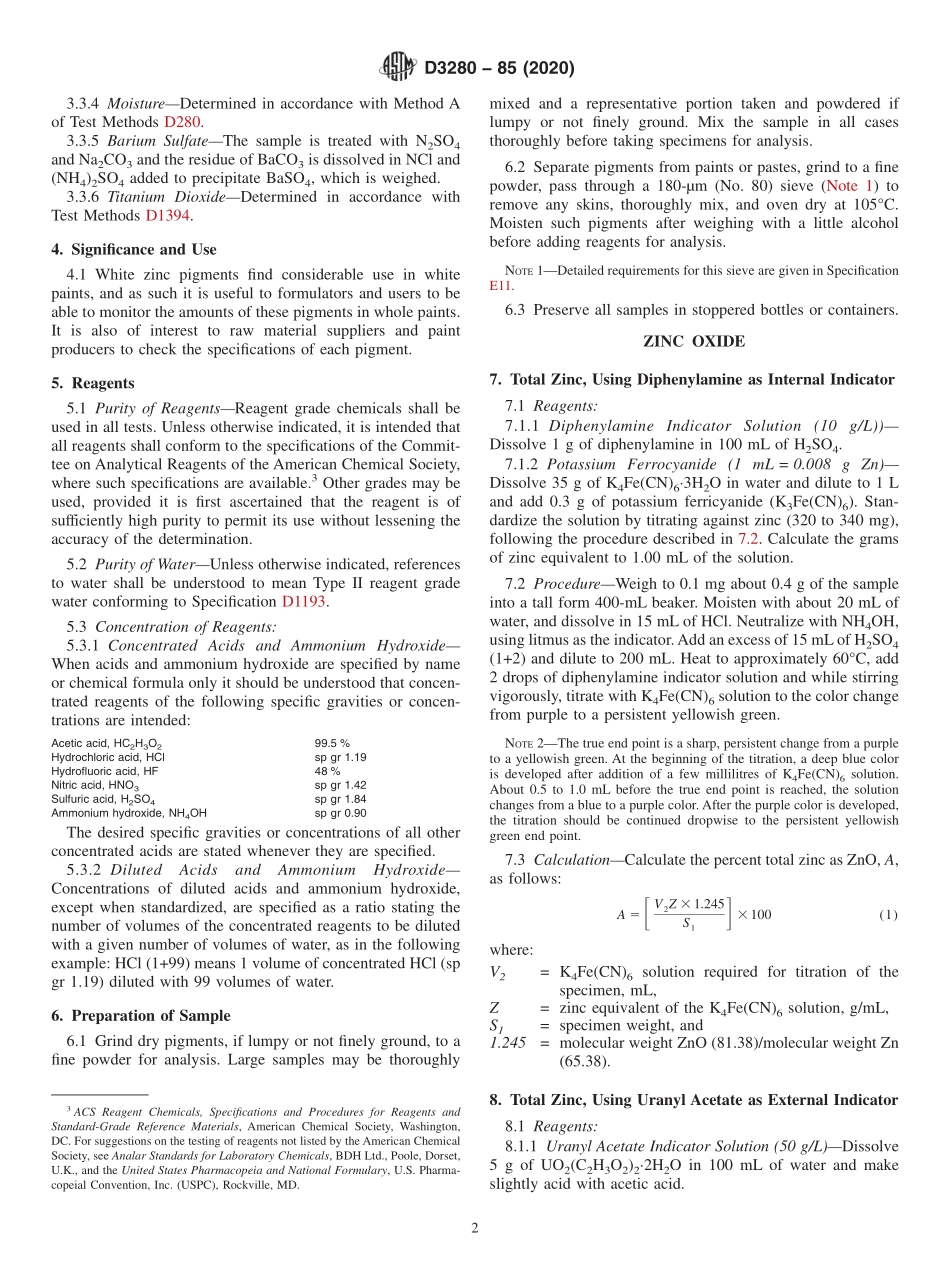

7.3 Calculation—Calculate the percent total zinc as ZnO, A, as follows:

![]()

where:

V2 = K4Fe(CN)6 solution required for titration of the specimen, mL,

Z = zinc equivalent of the K4Fe(CN)6 solution, g/mL, S1 = specimen weight, and

1.245 = molecular weight ZnO (81.38)/molecular weight Zn (65.38).

8. Total Zinc, Using Uranyl Acetate as External Indicator

8.1 Reagents:

8.1.1 Uranyl Acetate Indicator Solution (50 g/L)—Dissolve

5 g of UO2(C2H3O2)2·2H2O in 100 mL of water and make slightly acid with acetic acid.

![]() D3280 − 85 (2020)

D3280 − 85 (2020)

8.1.2 Potassium Ferrocyanide, Standard Solution (1 mL = 0.008 g Zn)—Prepare and standardize as in 7.1.2. Run a blank titration with the same amounts of reagents and water. Calculate the zinc equivalent of the solution as follows:

Z = W/(V 2 B ) (2)

where:

Z = zinc equivalent of the K4Fe(CN)6 solution, g/mL, W = zinc used,

V = K4Fe(CN)6 solution required for titration of the zinc, mL, and

B = K4Fe(CN)6 solution required for titration of the blank, mL.

8.2 Procedure:

8.2.1 Weigh to 0.1 mg about 0.4 g of the sample into a tall-form 400-mL beaker. Moisten with about 20 mL of water and dissolve by adding 10 mL of HCl. Add NH4OH until slightly alkaline to litmus paper. Add HCl until just acid, and then add 3 mL in excess. Dilute to about 250 mL with hot water and heat nearly to boiling. Titrate with K4Fe(CN)6 solution, stirring constantly, until a drop of uranyl acetate indicator tested in a white porcelain spot plate shows a brown tinge after standing 1 min.

8.2.2 Blank—Run a blank titration with the same amounts of reagents and water.

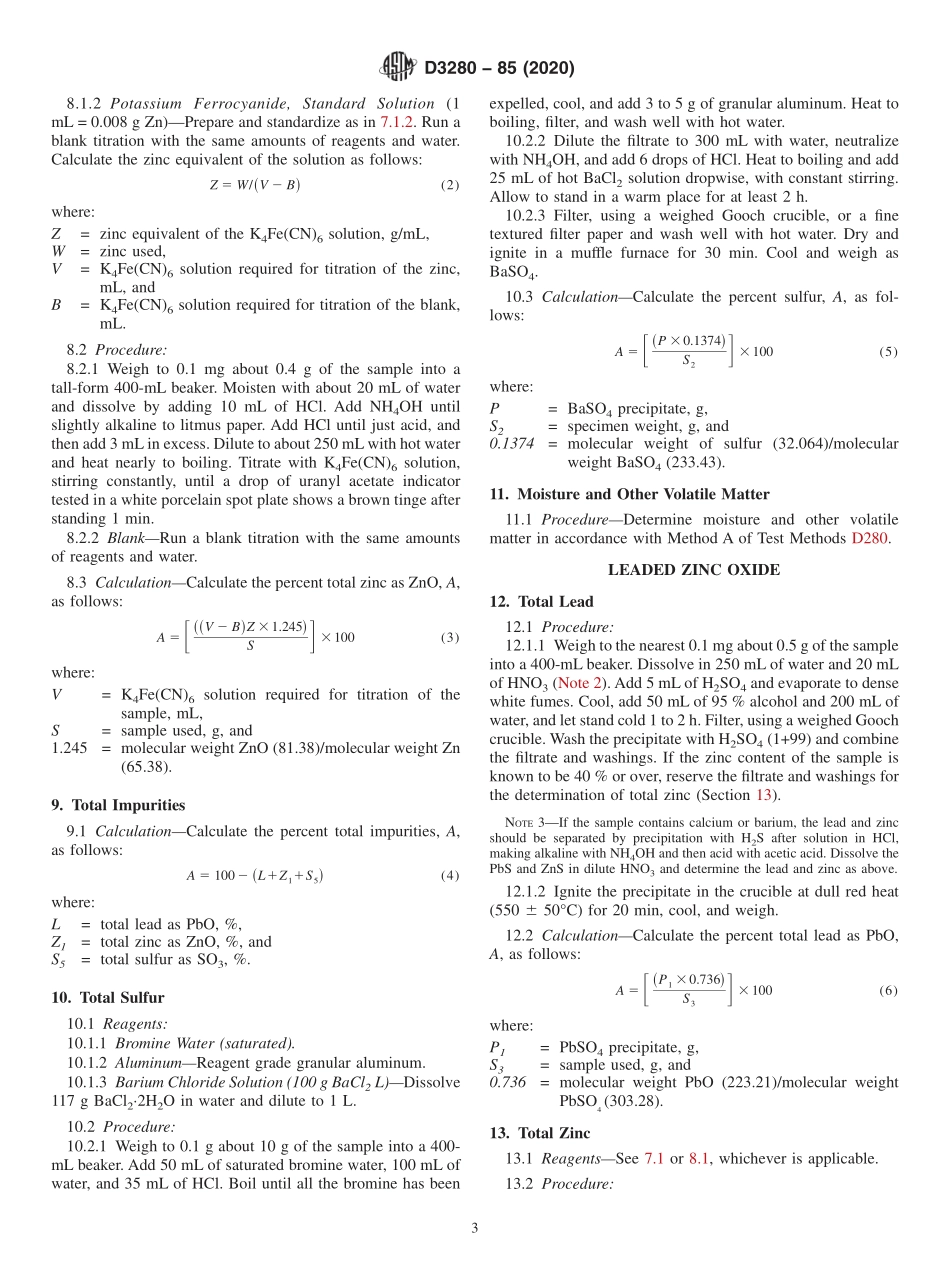

8.3 Calculation—Calculate the percent total zinc as ZnO, A, as follows:

![]()

where:

V = K4Fe(CN)6 solution required for titration of the

sample, mL,

S = sample used, g, and

1.245 = molecular weight ZnO (81.38)/molecular weight Zn (65.38).

9. Total Impurities

9.1 Calculation—Calculate the percent total impurities, A, as follows:

A = 100 2 (L +Z 1 +S5) (4)

where:

L = total lead as PbO, %,

Z1 = total zinc as ZnO, %, and S5 = total sulfur as SO3, %.

10. Total Sulfur

10.1 Reagents:

10.1.1 Bromine Water (saturated).

10.1.2 Aluminum—Reagent grade granular aluminum.

10.1.3 Barium Chloride Solution (100 g BaCl2 L)—Dissolve

117 g BaCl2·2H2O in water and dilute to 1 L.

10.2 Procedure:

10.2.1 Weigh to 0.1 g about 10 g of the sample into a 400- mL beaker. Add 50 mL of saturated bromine water, 100 mL of water, and 35 mL of HCl. Boil until all the bromine has been

expelled, cool, and add 3 to 5 g of granular aluminum. Heat to boiling, filter, and wash well with hot water.

10.2.2 Dilute the filtrate to 300 mL with water, neutralize with NH4OH, and add 6 drops of HCl. Heat to boiling and add 25 mL of hot BaCl2 solution dropwise, with constant stirring. Allow to stand in a warm place for at least 2 h.

10.2.3 Filter, using a weighed Gooch crucible, or a fine textured filter paper and wash well with hot water. Dry and ignite in a muffle furnace for 30 min. Cool and weigh as BaSO4.

10.3 Calculation—Calculate the percent sulfur, A, as fol- lows:

![]()

where:

P = BaSO4 precipitate, g,

S2 = specimen weight, g, and

0.1374 = molecular weight of sulfur (32.064)/molecular weight BaSO4 (233.43).

11. Moisture and Other Volatile Matter

11.1 Procedure—Determine moisture and other volatile matter in accordance with Method A of Test Methods D280.

LEADED ZINC OXIDE

12. Total Lead

12.1 Procedure:

12.1.1 Weigh to the nearest 0.1 mg about 0.5 g of the sample into a 400-mL beaker. Dissolve in 250 mL of water and 20 mL of HNO3 (Note 2). Add 5 mL of H2SO4 and evaporate to dense white fumes. Cool, add 50 mL of 95 % alcohol and 200 mL of water, and let stand cold 1 to 2 h. Filter, using a weighed Gooch crucible. Wash the precipitate with H2SO4 (1+99) and combine the filtrate and washings. If the zinc content of the sample is known to be 40 % or over, reserve the filtrate and washings for the determination of total zinc (Section 13).

NOTE 3—If the sample contains calcium or barium, the lead and zinc should be separated by precipitation with H2S after solution in HCl, making alkaline with NH4OH and then acid with acetic acid. Dissolve the PbS and ZnS in dilute HNO3 and determine the lead and zinc as above.

12.1.2 Ignite the precipitate in the crucible at dull red heat (550 ± 50°C) for 20 min, cool, and weigh.

12.2 Calculation—Calculate the percent total lead as PbO, A, as follows:

![]()

where:

P1 = PbSO4 precipitate, g, S3 = sample used, g, and

0.736 = molecular weight PbO (223.21)/molecular weight PbSO4 (303.28).

13. Total Zinc

13.1 Reagents—See 7.1 or 8.1, whichever is applicable.

13.2 Procedure:

![]() D3280 − 85 (2020)

D3280 − 85 (2020)

13.2.1 If the zinc content of the sample is known to be 40 % or over, determine zinc on the filtrate obtained in 12.1.1. If the zinc content is known to be under 40 %, weigh to the nearest 0.1 mg about 1 g of the sample, precipitate and filter off the lead as PbSO4 as described in 12.1.1, and determine zinc on the filtrate.

13.2.2 Evaporate the appropriate filtrate to dryness and determine zinc as directed in Sections 7 or 8.

14. Total Sulfur

14.1 Reagents—See 10.1.3.

14.2 Procedure:

14.2.1 Weigh to the nearest 0.1 mg about 1 g of the sample, into a 400-mL beaker. Add 10 mL of water, 3 g of NH4Cl, and 5 mL of HCl saturated with bromine. Heat on a steam bath for about 15 min. Add 50 mL of water, neutralize with dry Na2CO3 in excess. Boil 10 to 15 min. Allow to settle, dilute to 250 mL with hot water, filter, and wash with hot water.

14.2.2 Redissolve the residue in HCl, reprecipitate as before, and wash with hot water. Acidify the combined filtrates with HCl, adding 5 mL in excess. Boil 10 to 15 min. Neutralize with NH4OH and add 6 drops excess HCl. Heat to boiling and add 25 mL of hot BaCl2 solution dropwise, with constant stirring. Allow to stand in a warm place for at least 2 h.

14.2.3 Filter, using a weighed Gooch crucible or a fine textured filter paper, and wash well with hot water. Dry and ignite in a muffle furnace for 30 min. Cool and weigh.

14.3 Calculation—Calculate the percent sulfur as SO3, A, as follows:

![]()

where:

P2 = BaSO4 precipitate, g,

S4 = specimen weight, g, and

0.343 = molecular weight SO3 (80.07)/molecular weight BaSO4 (233.43).

15. Total Impurities

15.1 Calculation—Calculate the percent of total impurities, A, as follows:

A = 100 2 (L +Z 1 +S5) (8)

where:

L = total lead as PbO, %,

Z1 = total zinc as ZnO, %, and S5 = total sulfur as SO3, %.

16. Moisture and Other Volatile Matter

16.1 Procedure—Determine moisture and other volatile matter in accordance with Method A of Test Methods D280.

17. Water-Soluble Salts

17.1 Procedure:

17.1.1 Weigh to the nearest 1 mg about 5 g of the sample into a 500-mL graduated flask. Add 250 mL of water at room

temperature and shake for 10 min. Dilute the solution to the mark with water, mix by shaking, and filter through a dry, fine paper.

17.1.2 Transfer 400 mL of the clear filtrate to a weighed platinum dish and evaporate to dryness at 105 ± 2°C, cool in a desiccator, and weigh rapidly.

17.1.3 Blank—Make a blank determination at the same time in a similar manner.

17.2 Calculation—Calculate the percent water-soluble salts, W, as follows:

![]()

where:

R = dry salts obtained from the sample, g,

B2 = water-soluble salts obtained from the blank, g, and S5 = sample represented in the aliquot used, g.

ZINC SULFIDE

18. Zinc Oxide

18.1 Reagents—See 8.1.

18.2 Procedure:

18.2.1 Weigh to 1 mg about 5 g of the sample into a 500-mL Erlenmeyer flask and add 200 mL of acetic acid (3+97). Shake continuously for 20 min and transfer to a 500-mL volumetric flask. Dilute to the mark and filter through a dry, fine paper.

18.2.2 Transfer 400 mL of the clear filtrate to a 600-mL beaker. Add 20 mL of HCl and neutralize with NH4OH, using litmus paper. Add HCl until just acid and then add 3 mL in excess. Heat nearly to boiling and titrate with K4Fe(CN)6 solution as described in 8.2.

18.3 Calculation—Calculate the percent zinc oxide, A, as follows:

![]()

where:

V3 = K4Fe(CN)6 solution required for titration of the specimen, mL,

B3 = K4Fe(CN)6 solution required for titration of the blank, mL,

Z = zinc equivalent of the K4Fe(CN)6 solution, g/mL, S6 = sample represented in the aliquot used, g, and

1.245 = molecular weight ZnO (81.38)/molecular weight Zn (65.38).

19. Zinc Sulfide

19.1 Reagents—See Section 7 or 8, whichever is applicable.

19.2 Procedure—Weigh to the nearest 0.1 mg a portion of the sample into a tall-form 400-mL beaker. Moisten with water, add 10 mL of H2SO4 (1+1), and evaporate to dryness. Cool, and proceed as directed in 7.2 or 8.2.

19.3 Calculation—Calculate the percent zinc sulfide, C, as follows:

![]()

![]() D3280 − 85 (2020)

D3280 − 85 (2020)

where:

V4 = K4Fe(CN)6 solution required for titration of the specimen, mL,

B4 = K4Fe(CN)6 solution required for titration of the blank, mL,

Z = zinc equivalent of the K4Fe(CN)6 solution, g/mL, S7 = sample used, g,

A = percent of zinc oxide (Section 17),

1.20 = factor for conversion of percentage of ZnO to the ZnS equivalent, and

1.491 = molecular weight ZnS (97.44)/molecular weight Zn (65.38).

20. Water-Soluble Salts

20.1 Procedure—Determine water-soluble salts as directed in Section 17.

21. Moisture

21.1 Procedure—Determine moisture and other volatile matter in accordance with Method A of Test Methods D280.

22. Barium Sulfate

22.1 Reagents:

22.1.1 Ammonium Sulfate Solution (30 g/L)—Dissolve 30 g of (NH4)2SO4 in water and dilute to 1 L.

22.1.2 Methyl Orange Indicator Solution—Dissolve 0.1 g of methyl orange in 100 mL of water. Filter if necessary.

22.1.3 Sodium Carbonate Solution (2 g/L)—Dissolve 2 g of Na2CO3 in water and dilute to 1 L.

22.2 Procedure:

22.2.1 Weigh to the nearest 1 mg about 1 g of the sample into a 400-mL beaker. Moisten with water, and add 100 mL of H2SO4 (1+1), and evaporate to dryness. Cool, add 200 mL of water, and carefully break up the residue. Boil for 15 min. Filter, and wash with water.

22.2.2 Transfer the residue and paper to a platinum crucible and burn off the paper. Cool, add 6 g of Na2CO3, and mix. Cover with 2 g of Na2CO3, and fuse for 40 min over a Meker burner. Cool and leach the fusion with 200 mL of hot water in a 400-mL beaker. Filter and wash with hot Na2CO3 solution.

22.2.3 Dissolve the BaCO3 with hot HCl (1+4), catching the filtrate in a 600-mL beaker. Wash the paper with water. Neutralize with NH4OH, using methyl orange as the indicator. Add HCl until just acid and then add 6 drops in excess. Dilute to 400 mL, heat to boiling, and add 25 mL of hot (NH4)2SO4 solution slowly, while stirring. Allow to stand in a warm place for at least 4 h.

22.2.4 Filter off the precipitate, using a weighed Gooch crucible or a fine textured filter paper, and wash with hot water until free of chlorides. Dry, ignite in a muffle furnace for 30 min, cool, and weigh.

22.3 Calculation—Calculate the percent barium sulfate (BaSO4), A, as follows:

![]()

where:

P3 = BaSO4 precipitate, g, and S8 = sample used, g.

23. Titanium Dioxide

23.1 Procedure—Determine titanium dioxide in accordance with Sections 9 to 13 of Test Methods D1394. If the pigment being analyzed is relatively low in TiO2, the use of a larger specimen than that specified in Test Methods D1394 should give more accurate results.

24. Keywords

24.1 analysis; barium sulfate; lead; sulfur; uranyl acetate; white zinc pigment; zinc

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards and should be addressed toASTM International Headquarters. Your comments will receive careful consideration at a meeting of the responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website (www.astm.org). Permission rights to photocopy the standard may also be secured from the Copyright Clearance Center, 222 Rosewood Drive, Danvers, MA 01923, Tel: (978) 646-2600; http://www.copyright.com/

1、当您付费下载文档后,您只拥有了使用权限,并不意味着购买了版权,文档只能用于自身使用,不得用于其他商业用途(如 [转卖]进行直接盈利或[编辑后售卖]进行间接盈利)。

2、本站所有内容均由合作方或网友上传,本站不对文档的完整性、权威性及其观点立场正确性做任何保证或承诺!文档内容仅供研究参考,付费前请自行鉴别。

3、如文档内容存在违规,或者侵犯商业秘密、侵犯著作权等,请点击“违规举报”。

碎片内容