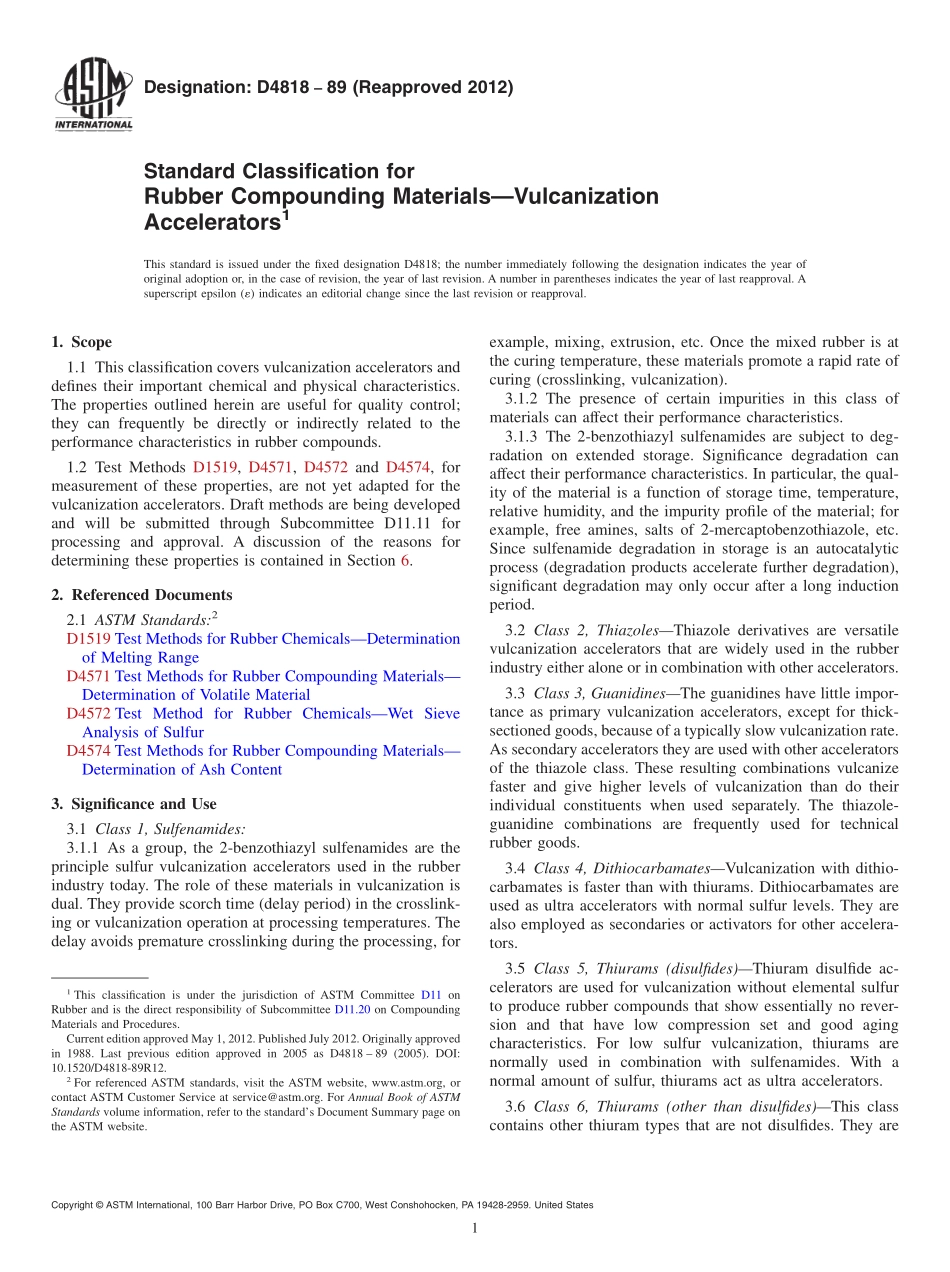

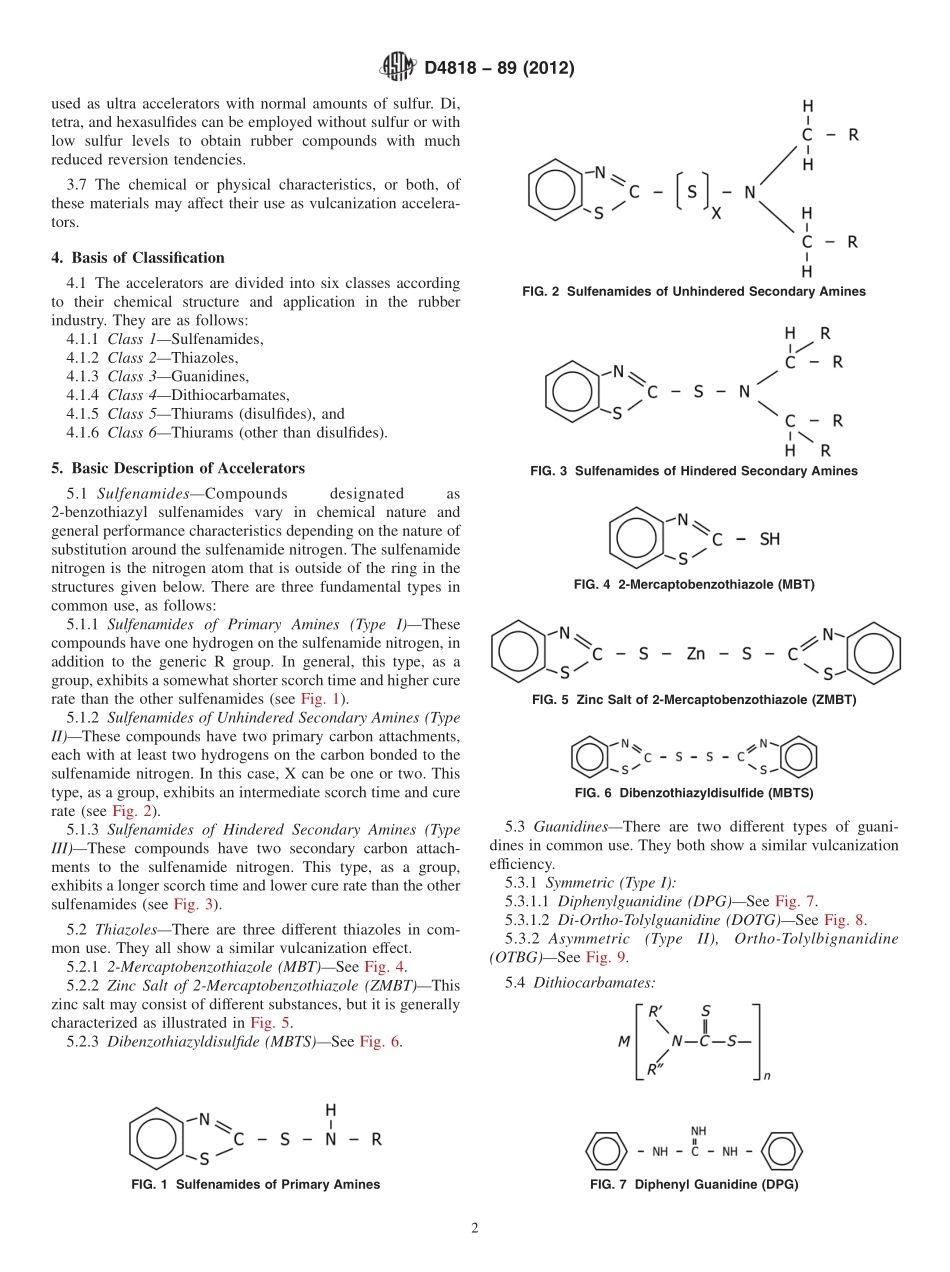

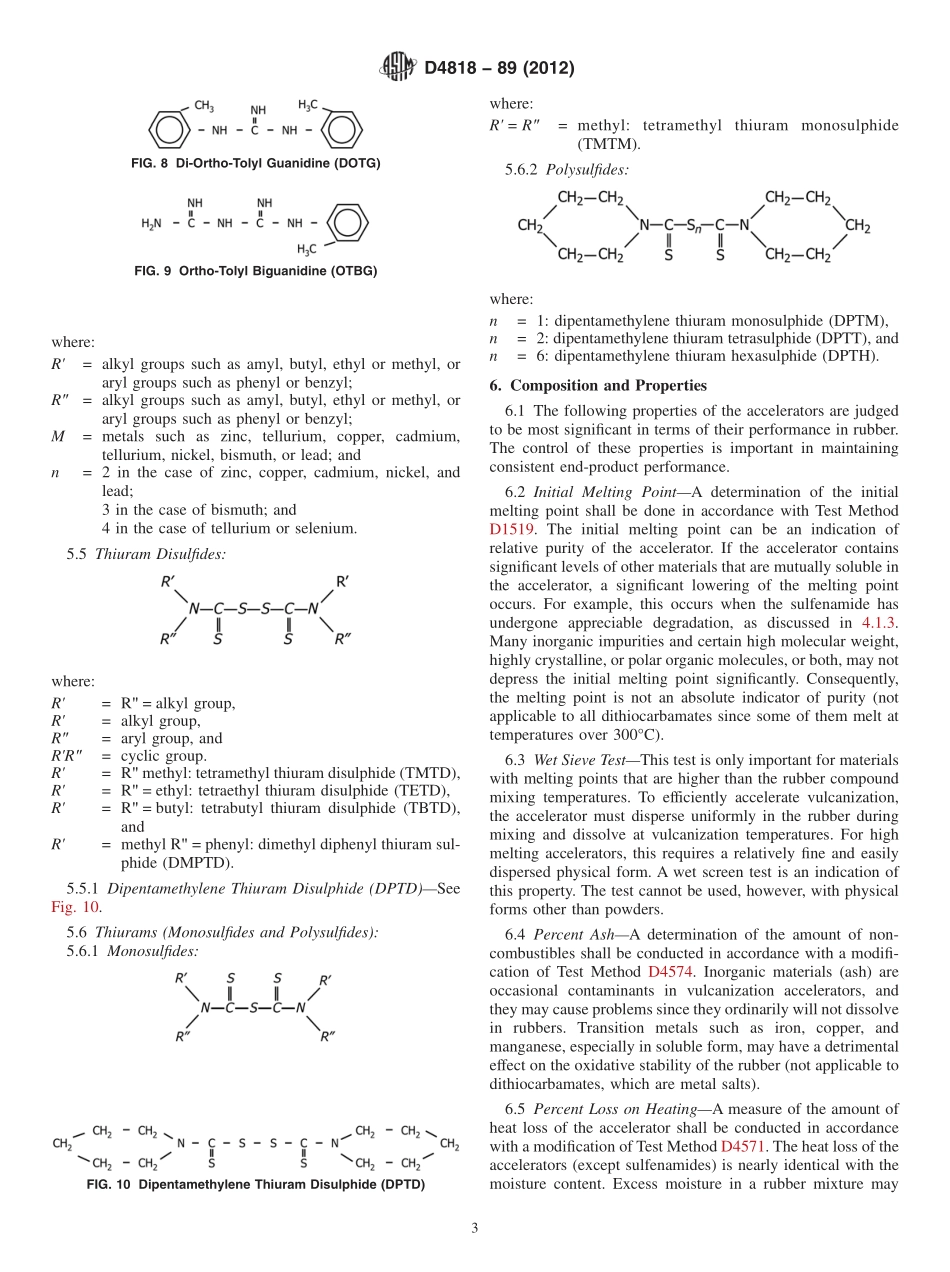

Designation:D4818−89(Reapproved2012)StandardClassificationforRubberCompoundingMaterials—VulcanizationAccelerators1ThisstandardisissuedunderthefixeddesignationD4818;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thisclassificationcoversvulcanizationacceleratorsanddefinestheirimportantchemicalandphysicalcharacteristics.Thepropertiesoutlinedhereinareusefulforqualitycontrol;theycanfrequentlybedirectlyorindirectlyrelatedtotheperformancecharacteristicsinrubbercompounds.1.2TestMethodsD1519,D4571,D4572andD4574,formeasurementoftheseproperties,arenotyetadaptedforthevulcanizationaccelerators.DraftmethodsarebeingdevelopedandwillbesubmittedthroughSubcommitteeD11.11forprocessingandapproval.AdiscussionofthereasonsfordeterminingthesepropertiesiscontainedinSection6.2.ReferencedDocuments2.1ASTMStandards:2D1519TestMethodsforRubberChemicals—DeterminationofMeltingRangeD4571TestMethodsforRubberCompoundingMaterials—DeterminationofVolatileMaterialD4572TestMethodforRubberChemicals—WetSieveAnalysisofSulfurD4574TestMethodsforRubberCompoundingMaterials—DeterminationofAshContent3.SignificanceandUse3.1Class1,Sulfenamides:3.1.1Asagroup,the2-benzothiazylsulfenamidesaretheprinciplesulfurvulcanizationacceleratorsusedintherubberindustrytoday.Theroleofthesematerialsinvulcanizationisdual.Theyprovidescorchtime(delayperiod)inthecrosslink-ingorvulcanizationoperationatprocessingtemperatures.Thedelayavoidsprematurecrosslinkingduringtheprocessing,forexample,mixing,extrusion,etc.Oncethemixedrubberisatthecuringtemperature,thesematerialspromotearapidrateofcuring(crosslinking,vulcanization).3.1.2Thepresenceofcertainimpuritiesinthisclassofmaterialscanaffecttheirperformancecharacteristics.3.1.3The2-benzothiazylsulfenamidesaresubjecttodeg-radationonextendedstorage.Significancedegradationcan...