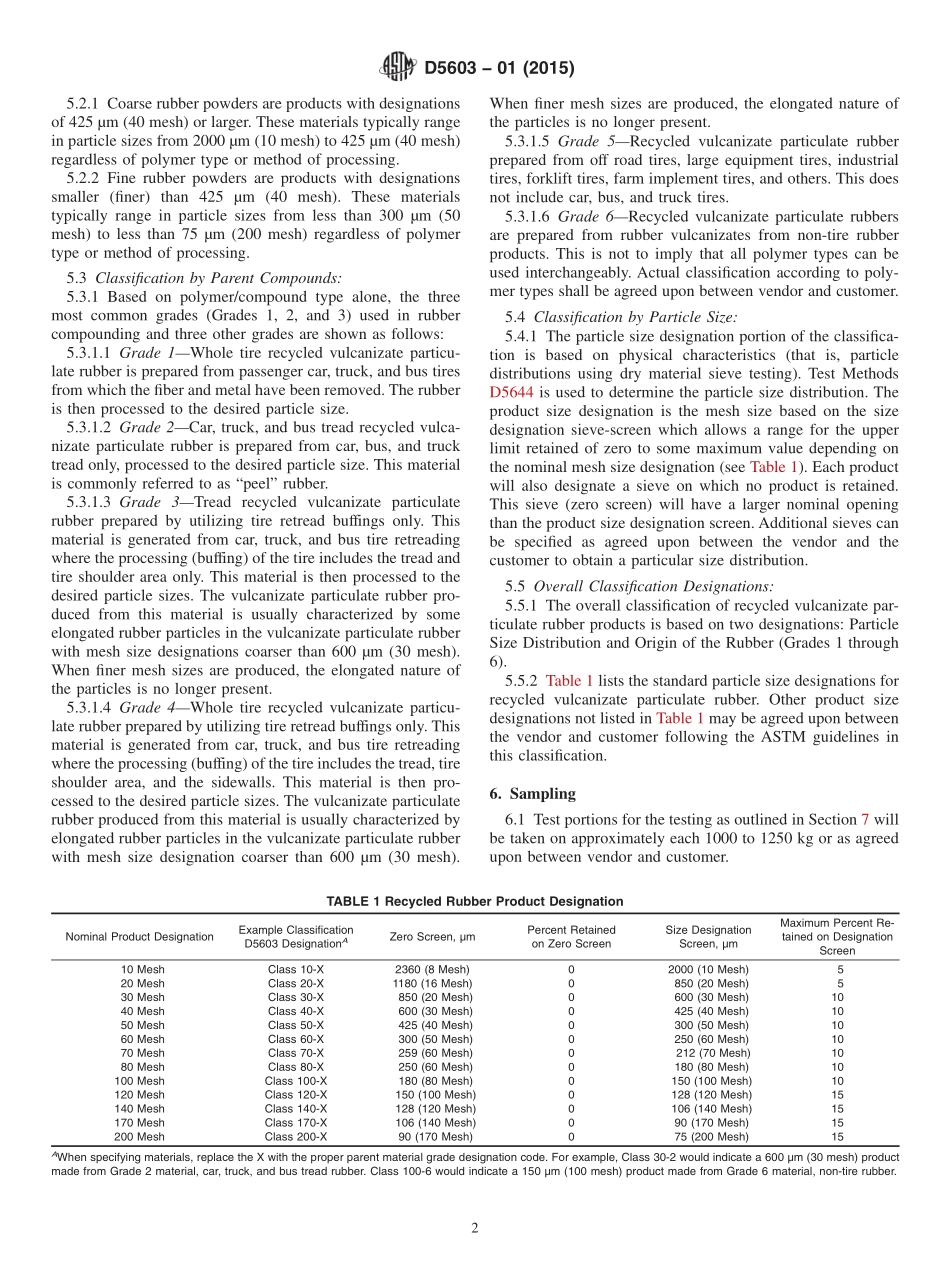

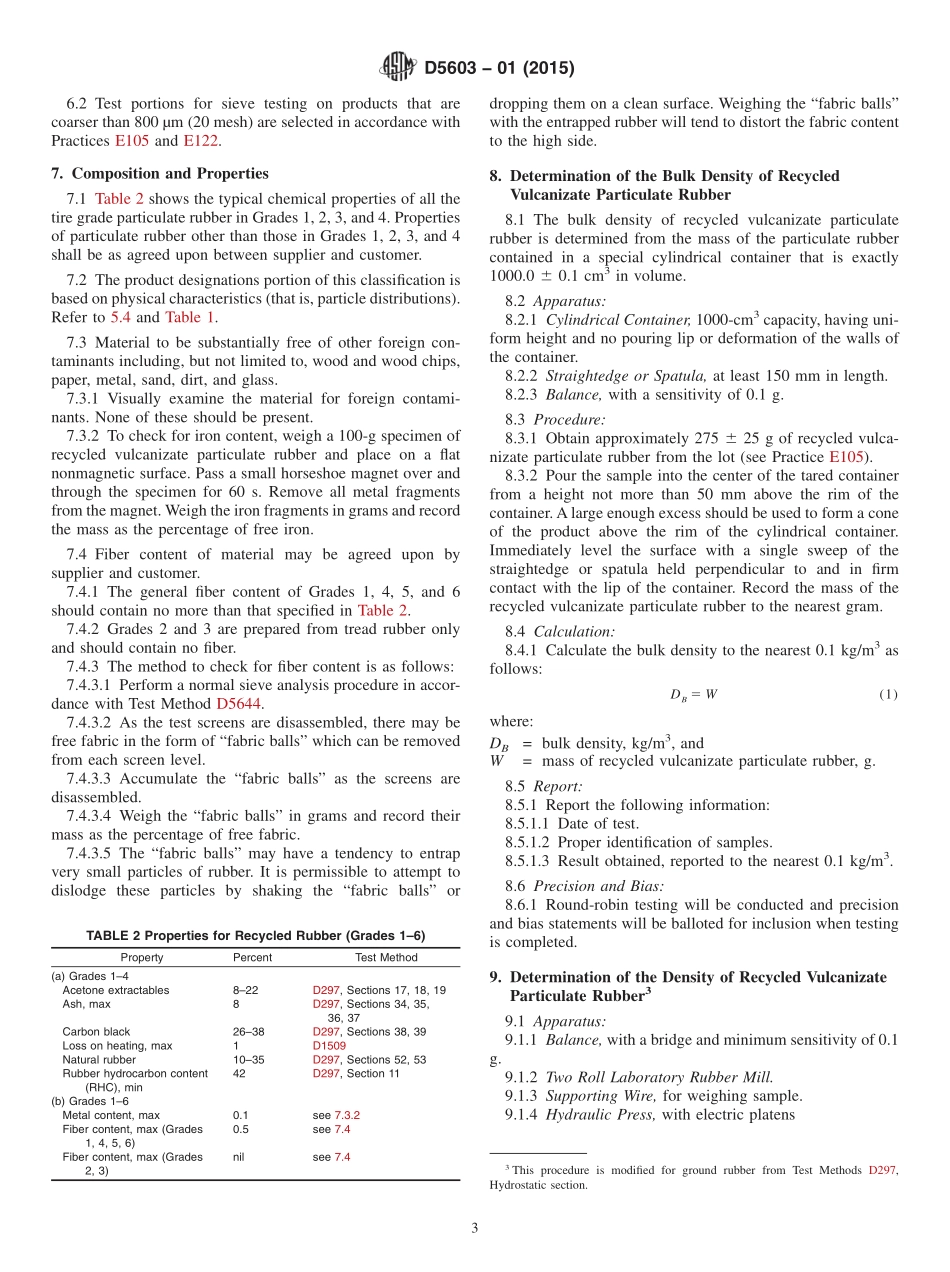

Designation:D5603−01(Reapproved2015)StandardClassificationforRubberCompoundingMaterials—RecycledVulcanizateParticulateRubber1ThisstandardisissuedunderthefixeddesignationD5603;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thisclassificationcoversthecompoundingmaterialcommerciallyknownasrecycledvulcanizateparticulaterub-ber.Recycledvulcanizateparticulaterubberistheproductthatresultswhenvulcanizaterubberhasbeenprocessedbysomemeanstoobtainadesiredparticlesizedistribution.1.2ThevaluesstatedinSIunitsaretoberegardedasstandard.Nootherunitsofmeasurementareincludedinthisstandard.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D297TestMethodsforRubberProducts—ChemicalAnaly-sisD1418PracticeforRubberandRubberLatices—NomenclatureD1509TestMethodsforCarbonBlack—HeatingLossD1566TerminologyRelatingtoRubberD1900PracticeforCarbonBlack—SamplingBulkShip-mentsD3182PracticeforRubber—Materials,Equipment,andPro-ceduresforMixingStandardCompoundsandPreparingStandardVulcanizedSheetsD4483PracticeforEvaluatingPrecisionforTestMethodStandardsintheRubberandCarbonBlackManufacturingIndustriesD5644TestMethodsforRubberCompoundingMaterials—DeterminationofParticleSizeDistributionofRecycledVulcanizateParticulateRubberE11SpecificationforWovenWireTestSieveClothandTestSievesE105PracticeforProbabilitySamplingofMaterialsE122PracticeforCalculatingSampleSizetoEstimate,WithSpecifiedPrecision,theAverageforaCharacteristicofaLotorProcess3.Terminology3.1Definitions:3.1.1recycledvulcanizateparticulaterubber,n—recyclablevulcanizaterubberthathasbeenprocessedtogive...