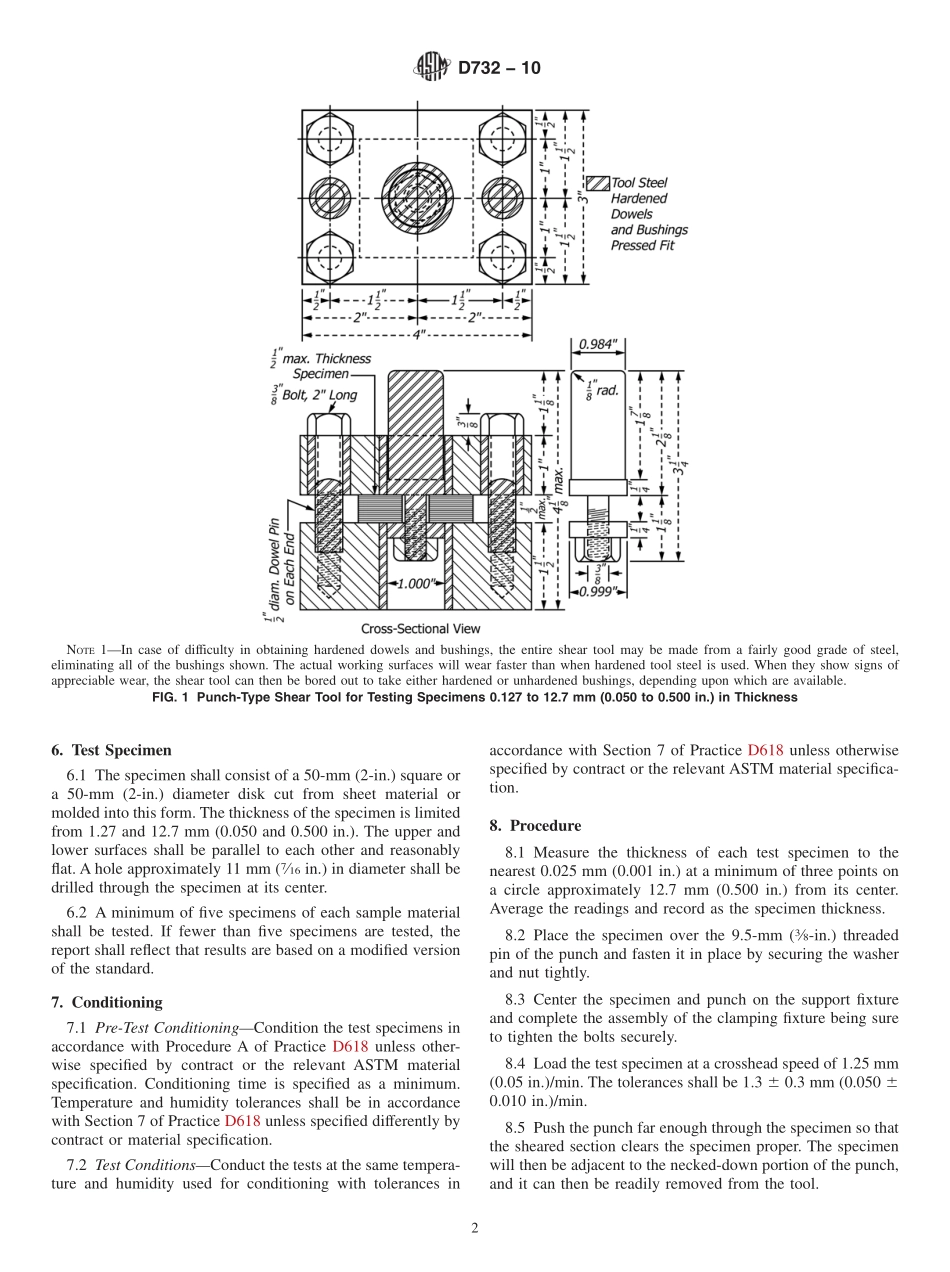

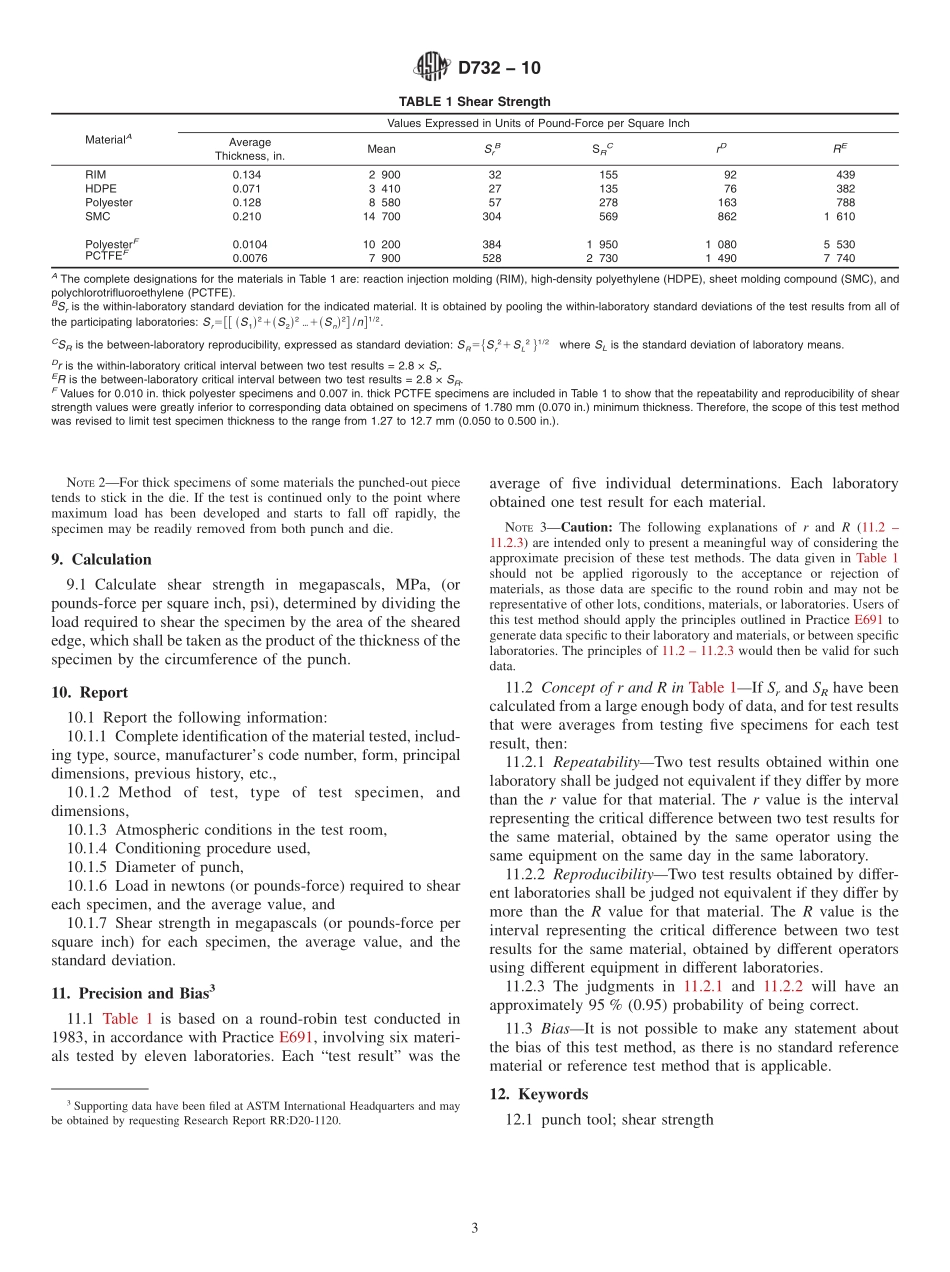

Designation:D732−10StandardTestMethodforShearStrengthofPlasticsbyPunchTool1ThisstandardisissuedunderthefixeddesignationD732;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheU.S.DepartmentofDefense.1.Scope*1.1Thistestmethodcoverstheprocedurefordeterminingtheshearstrengthofcompositematerialsintheformofsheets,plates,andmoldedshapesinthicknessesfrom1.27to12.7mm(0.050to0.500in.).1.2ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.NOTE1—ThereisnoknownISOequivalenttothisstandard.2.ReferencedDocuments2.1ASTMStandards:2D618PracticeforConditioningPlasticsforTestingD4000ClassificationSystemforSpecifyingPlasticMateri-alsE4PracticesforForceVerificationofTestingMachinesE691PracticeforConductinganInterlaboratoryStudytoDeterminethePrecisionofaTestMethod3.Terminology3.1Definitions:3.1.1shearstrength—themaximumloadrequiredtoshearthespecimeninsuchamannerthatthemovingportionoftheloadfixturehascompletelyclearedthestationaryportion,dividedbytheshearedarea.Itisexpressedinmegapascals(orpounds-forcepersquareinch)basedontheareaoftheshearededgeoredges.4.SignificanceandUse4.1Shearstrengthobtainedbytheuseofpunch-typetoolingisoneoftherecognizedmethodsofcomparingmaterials,orobtainingdataforengineeringdesignpurposes,orboth.However,itmustberecognizedthatforend-useapplicationstherearelikelytobemanyfactorsnottakenintoaccountinthistestmethod,suchasstress-concentratinggeometriesandratesofshear,whichcanprofoundlyaffectthemeasuredshearstrength.Moreover,thefa...