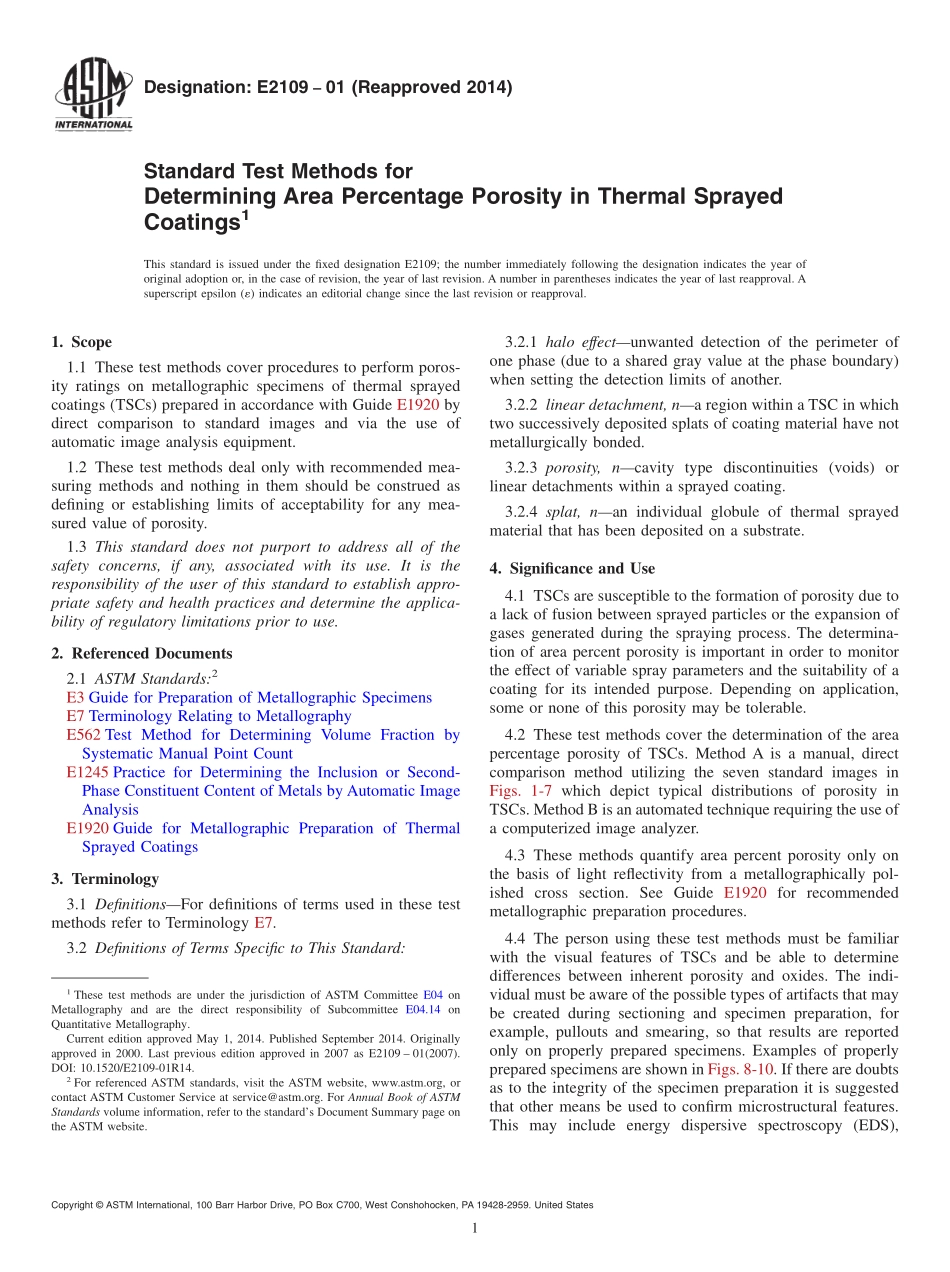

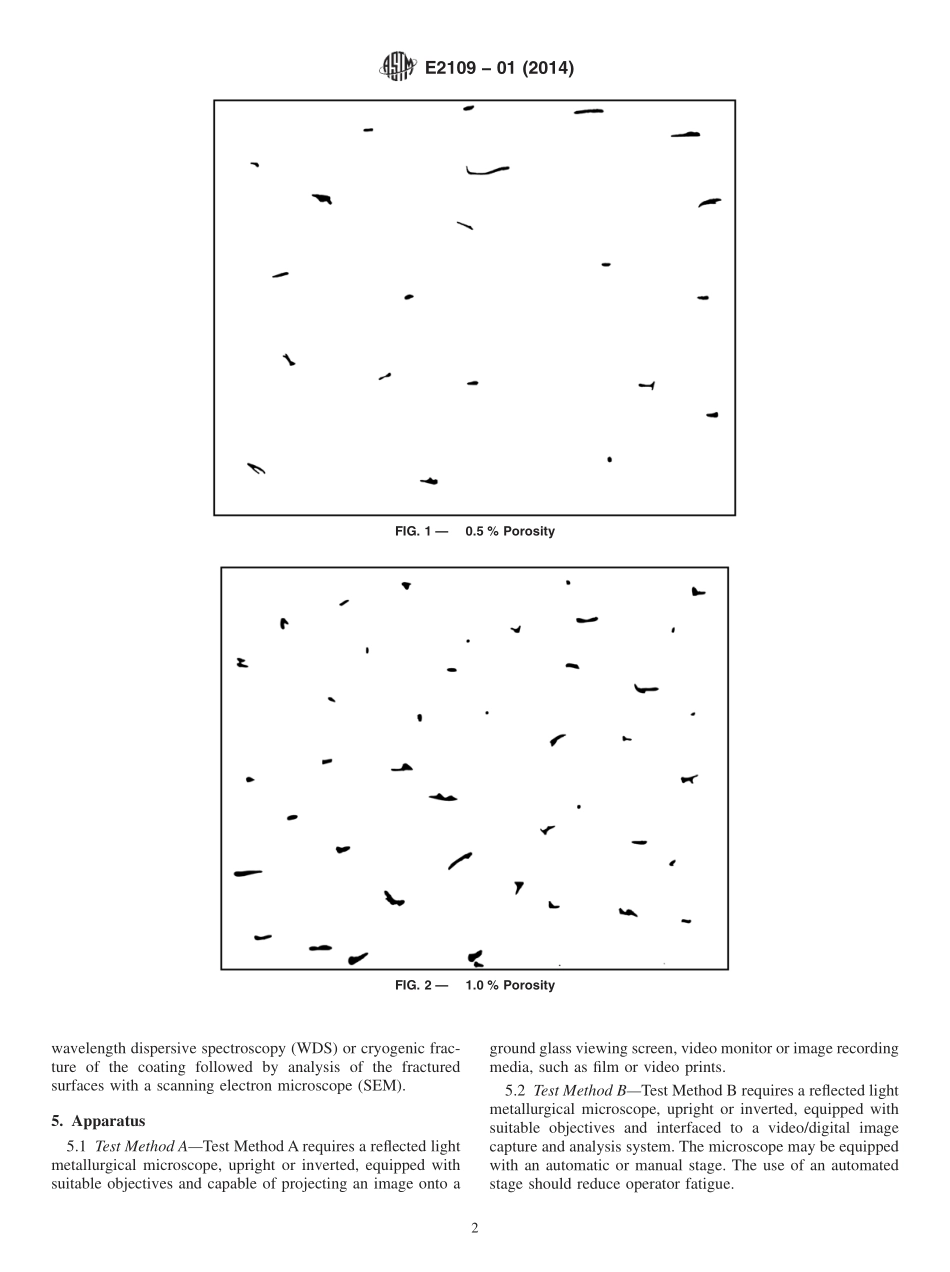

Designation:E2109−01(Reapproved2014)StandardTestMethodsforDeterminingAreaPercentagePorosityinThermalSprayedCoatings1ThisstandardisissuedunderthefixeddesignationE2109;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thesetestmethodscoverprocedurestoperformporos-ityratingsonmetallographicspecimensofthermalsprayedcoatings(TSCs)preparedinaccordancewithGuideE1920bydirectcomparisontostandardimagesandviatheuseofautomaticimageanalysisequipment.1.2Thesetestmethodsdealonlywithrecommendedmea-suringmethodsandnothinginthemshouldbeconstruedasdefiningorestablishinglimitsofacceptabilityforanymea-suredvalueofporosity.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2E3GuideforPreparationofMetallographicSpecimensE7TerminologyRelatingtoMetallographyE562TestMethodforDeterminingVolumeFractionbySystematicManualPointCountE1245PracticeforDeterminingtheInclusionorSecond-PhaseConstituentContentofMetalsbyAutomaticImageAnalysisE1920GuideforMetallographicPreparationofThermalSprayedCoatings3.Terminology3.1Definitions—FordefinitionsoftermsusedinthesetestmethodsrefertoTerminologyE7.3.2DefinitionsofTermsSpecifictoThisStandard:3.2.1haloeffect—unwanteddetectionoftheperimeterofonephase(duetoasharedgrayvalueatthephaseboundary)whensettingthedetectionlimitsofanother.3.2.2lineardetachment,n—aregionwithinaTSCinwhichtwosuccessivelydepositedsplatsofcoatingmaterialhavenotmetallurgicallybonded.3.2.3porosity,n—cavitytypediscontinuities(voids)orlineardetachmentswithinasprayedcoating.3.2.4splat,n—anindividualglobuleofthermalsprayedmaterialthathasbeendepositedonasu...