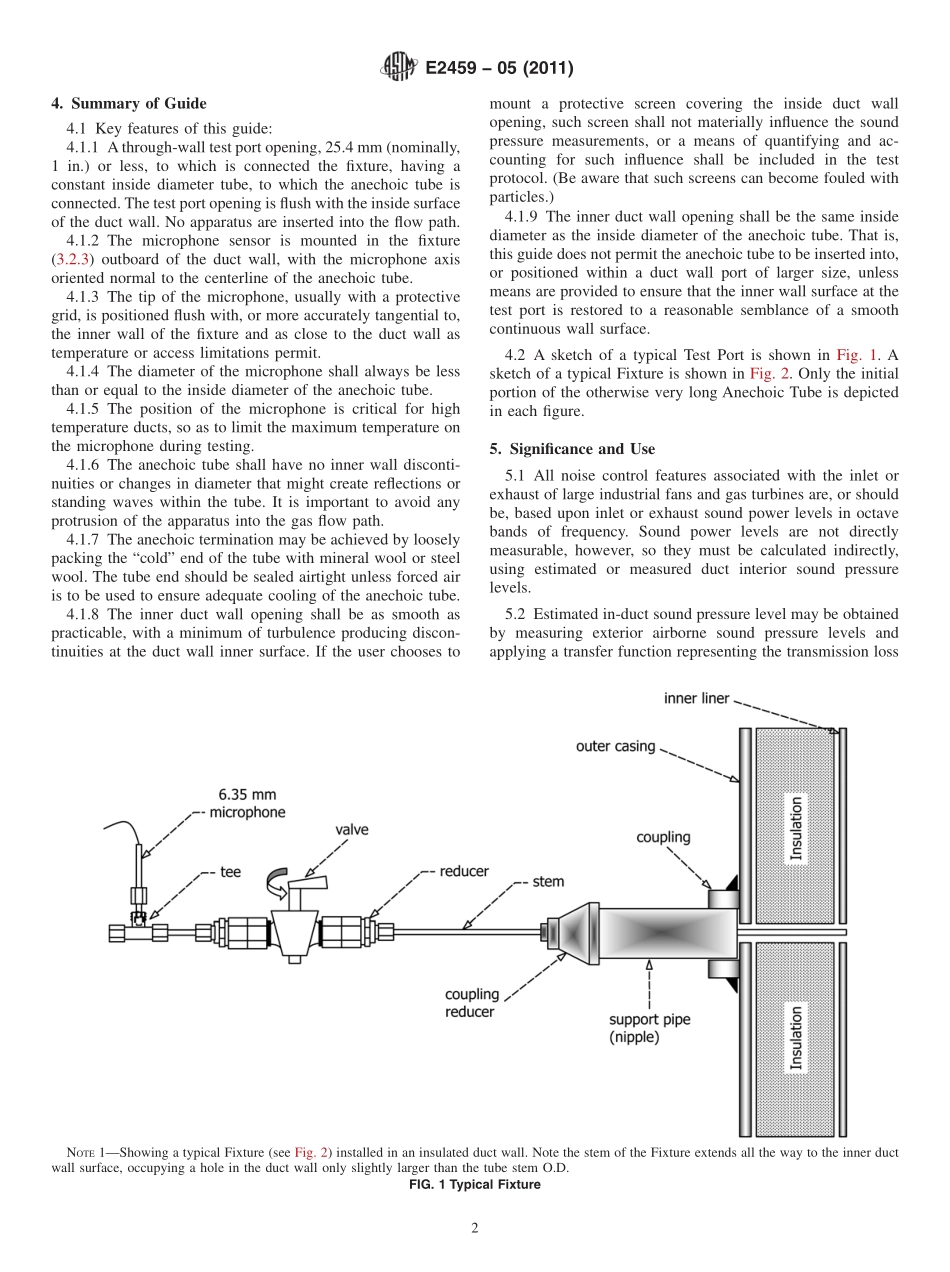

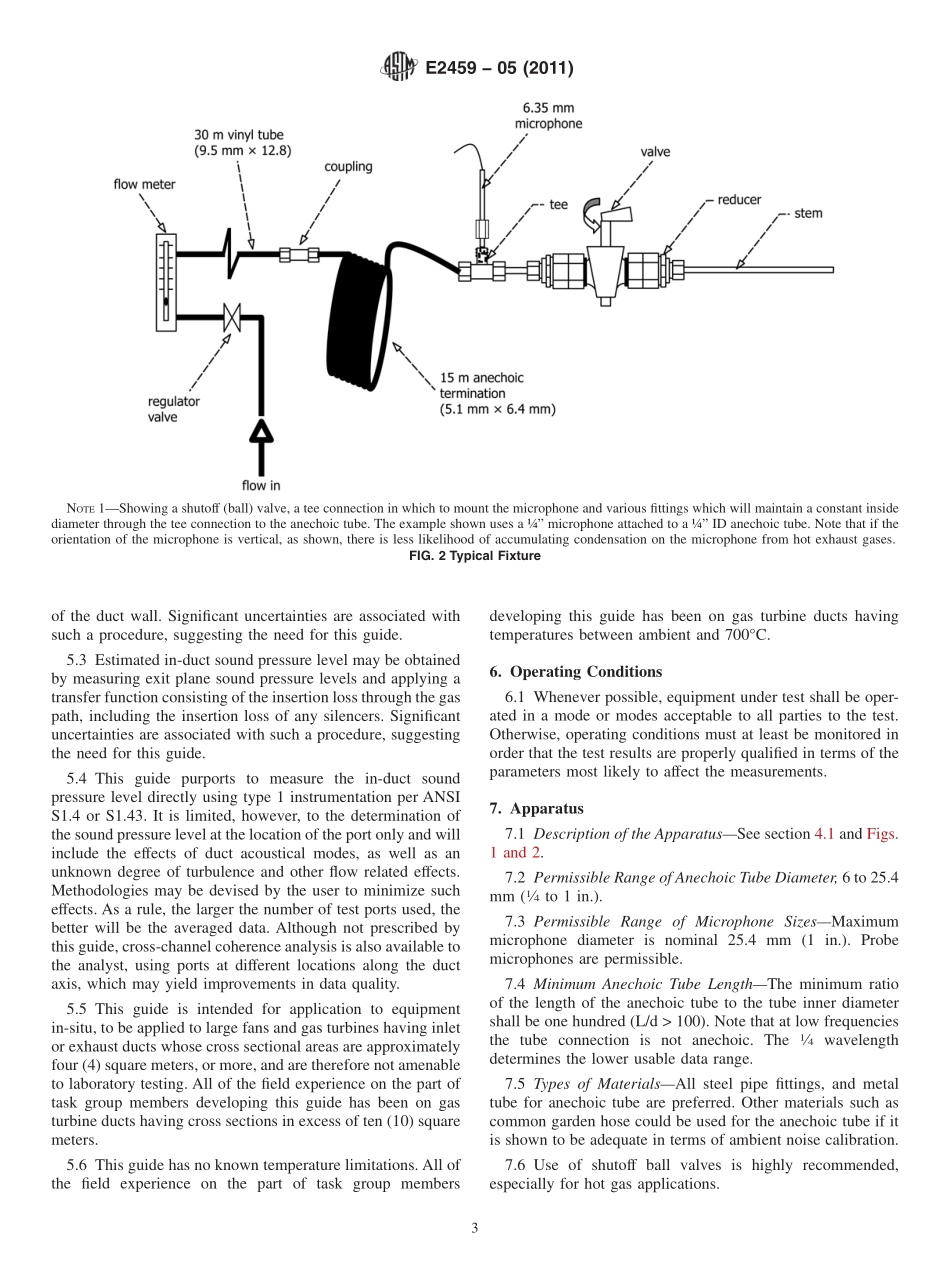

Designation:E2459−05(Reapproved2011)StandardGuideforMeasurementofIn-DuctSoundPressureLevelsfromLargeIndustrialGasTurbinesandFans1ThisstandardisissuedunderthefixeddesignationE2459;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thisguideisintendedtoprovideasimpleandconsistentprocedureforthein-situfieldmeasurementofin-ductsoundpressurelevelsinlargelowpressureindustrialairducts,suchasforgasturbinesorfans,whereconsiderationssuchasflowvelocity,turbulenceortemperaturepreventtheinsertionofsoundpressuresensorsdirectlyintotheflow.Thisstandardguideisintendedforbothambienttemperatureintakeairandhotexhaustgasflowinductshavingcrosssectionsoffour(4)squaremeters,ormore.1.2Thedescribedprocedureisintendedtoprovidearepeat-ableandreproduciblemeasureofthein-ductdynamicpressurelevelattheinletorexhaustofthegasturbine,orfan.Theguideisnotintendedtoquantifythe“true”soundpressurelevelorsoundpowerlevel.Silencers,aswellasWasteHeatBoilers,mustbedesignedusingthein-ductsoundpowerlevelasthebasis.Developingthetruesoundpowerlevelbasedonin-ductmeasurementsoftruesoundpressurewithinacompleteoper-atingsystemiscomplexandproceduresaredevelopmentalandoftenproprietary.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.Extremecautionismandatorywhenworkingnearhotexhaustgassystemsandappropriatesafetyprecautionssuchastheinstallationofquickactingisolationvalvesarerecommended.2.ReferencedDocuments2.1ASTMStandards:2C634TerminologyRelatingtoBuildingandEnvironmentalAcoustics2.2ANSIStandards:S1.4SpecificationforSoundLevelMeters3S1.43SpecificationforIntegratingAveragingSoundLevelMeters33.Terminology3.1Definiti...