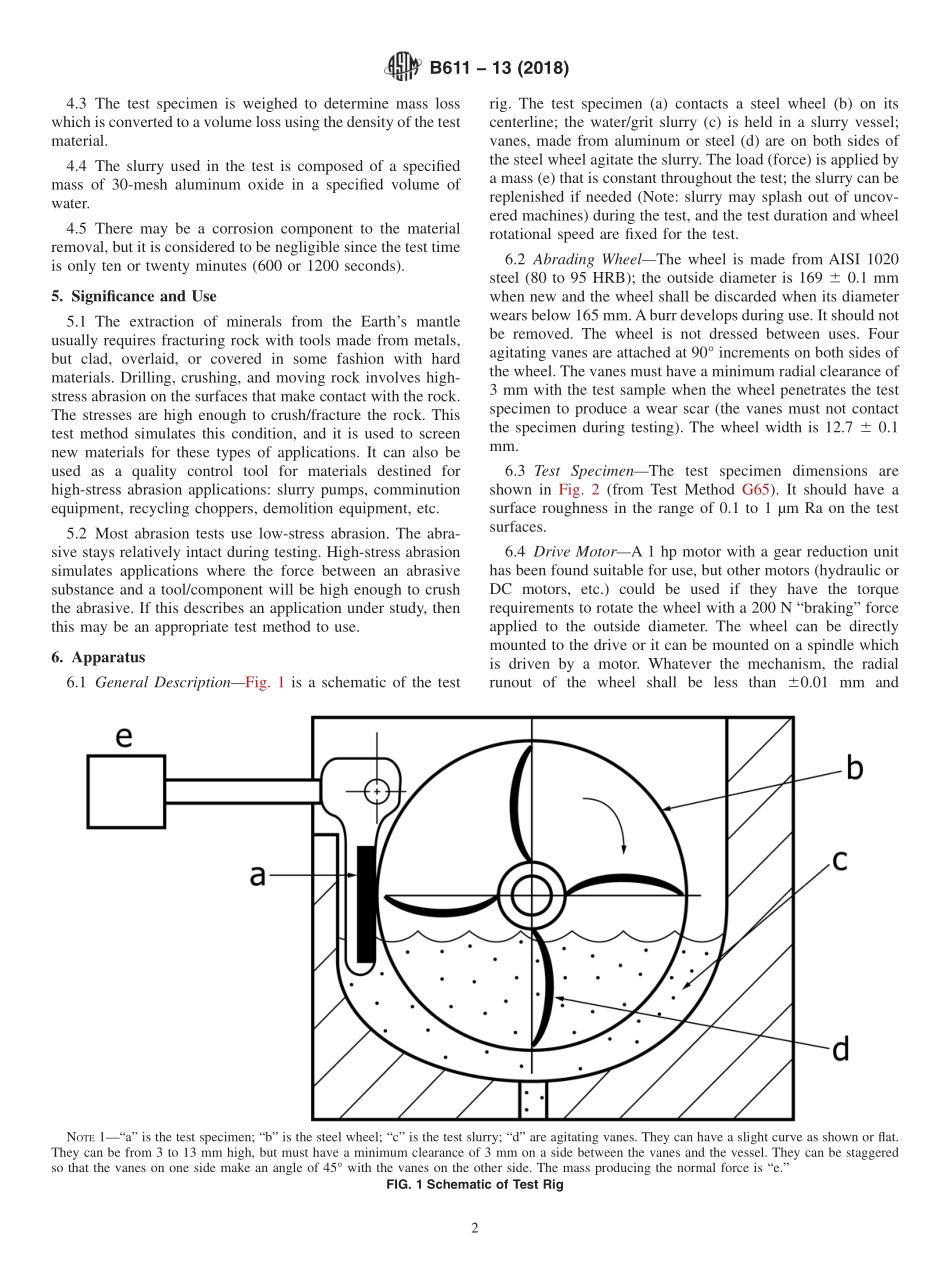

Designation:B611−13(Reapproved2018)StandardTestMethodforDeterminingtheHighStressAbrasionResistanceofHardMaterials1ThisstandardisissuedunderthefixeddesignationB611;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodwasdevelopedforrankingthehigh-stressabrasionresistanceofcementedcarbides,butithasbeensuccessfullyusedonceramics,cermets,andmetalmatrixhardfacingswithahardnessover55HRC.Thefeatureofthistestmethodthatdiscriminatesitfromotherabrasiontestsisthattheabrasiveisforcedagainstthetestspecimenwithasteelwheelwithsufficientforcetocausefractureoftheabrasiveparticles.Someabrasiontestsuserubberwheelstoforceabrasiveagainsttestsurfaces(TestMethodsG65,G105,G75).Arubberwheelproduceslow-stressabrasionwhileasteelwheelproduceshigh-stressabrasion.1.2Insummary,thisisahigh-stresslaboratoryabrasiontestforhardmaterialsusingawaterslurryofaluminumoxideparticlesastheabrasivemediumandarotatingsteelwheeltoforcetheabrasiveacrossaflattestspecimeninlinecontactwiththerotatingwheelimmersedintheslurry.1.3ThevaluesstatedinSIunitsaretoberegardedasstandard.Nootherunitsofmeasurementareincludedinthisstandard.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafety,health,andenvironmentalpracticesanddeter-minetheapplicabilityofregulatorylimitationspriortouse.1.5Thisinternationalstandardwasdevelopedinaccor-dancewithinternationallyrecognizedprinciplesonstandard-izationestablishedintheDecisiononPrinciplesfortheDevelopmentofInternationalStandards,GuidesandRecom-mendationsissuedbytheWorldTradeOrganizationTechnicalBarrierstoTrade(TBT)Committee.2.ReferencedDocuments2.1ASTMStandards:2B311TestMethodforDensityofPowderMetallurgy(PM)MaterialsContainingLessThanTwoPercentPorosityG40...